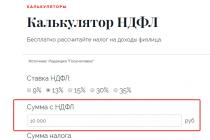

V general view is a screw pile connected over the piles with a grillage. In the inner contour of the foundation, the floor of the first floor is made.

Warming pile foundation perform by insulating the grillage and the floor of the first floor. Piles themselves do not insulate, regardless of soil and climatic conditions.

The grillage can be low and high - in both cases, the outer surface of the grillage is insulated to its entire height. And also insulate the bottom of the grillage, as shown in the figures below:

In the inner contour of the foundation, the floor of the first floor is arranged. This floor is usually performed in three versions: concrete, wooden floor along the logs or the concrete floor of the first floor along the floor slabs. Consider how to perform the insulation of a pile foundation with all three types of floors.

Insulation of a pile foundation with a concrete floor on the ground

The floor, made according to this scheme, is insulated, as shown in the figures, under the finishing screed:

Insulation of a pile foundation with a floor on floor slabs

How to insulate a pile foundation

Let's describe all the types of grillage and floor given above and the material for their insulation.

Both low and high grillage are insulated with EPPS (insulation thickness calculated for a specific region, but not less than 50 mm).

The floor on the ground is insulated either with EPPS or with foam plastic, density 30 kg / m3.

The floor along the logs is insulated with mineral wool, density 30-60 kg / m3 (insulation thickness according to the calculation for a particular region)

The floor on the finished factory plate is insulated from below with EPPS (the thickness of the insulation according to the calculation for a particular region). The floor on the finished factory plate is insulated from above with EPPS or foam plastic, density 30 kg / m3 (insulation thickness according to the calculation for a particular region).

In some cases, pile foundations have an advantage over columnar, strip and slab foundations. This is especially true with a significant depth of soil freezing, in wetlands, in areas with a high layer of loose soils, as well as with large slopes and elevations of construction sites. Savings due to the choice of pile technology can reach 50% or more. However, developers need to plan an additional budget for the insulation of the pile foundation. The tasks solved by thermal insulation and methods of its construction are described in this article.

For low-rise construction, reinforced concrete piles of a solid section, steel screw and bored concrete piles are most suitable. Regardless of the design of the piles, the method of their installation and the technology of mounting the grillage, this type of foundation has a number of disadvantages.

Disadvantages of a pile foundation:

A pile foundation that is not insulated during the cold season can lead to big problems.

- Cold underground. Increased heat loss through the floor in winter period.

- If the grillage is made of reinforced concrete, then a powerful cold accumulator is created. In case of interruptions in heating, it takes a very long time (up to several days) to restore the normal microclimate in such a room.

- Danger of freezing of utilities laid under the floor.

- Pushing piles that have fallen into the freezing zone. Piles are a conductor of cold. If antifreeze measures are not provided, metal and concrete supports can cause local heaving.

- Uneven shrinkage under the weight of the house when individual piles enter zones of low soil density.

- From an aesthetic point of view, a conventional pile foundation is a purely utilitarian design solution that requires decoration.

- The void under the house, blown by the winds, quickly becomes littered and periodically takes time to restore order under home.

Why are individual piles pushed out, leading to a situation where the grillage plane is violated? One of the common reasons is uneven soil moisture: it is stronger around the perimeter and corners than in the center. This, in turn, leads to uneven freezing depth. In addition, the specific expansion during heaving also depends on the percentage of moisture.

4 of the 7 problems listed are directly related to exposure to cold and are solved with the help of a competent thermal insulation device.

Insulation of the foundation, made according to the pile scheme with reinforced concrete grillage

This or that decision on thermal insulation is made depending on the height of the base. Small heights make it appropriate to arrange sexes on the ground. In this case, the principle of insulation is the same as in the uff scheme.

Rostverk, like MZLF, perceives the load only from the walls. The floor slab is cast over the layer of polystyrene boards. The slabs are laid out on a compacted sand cushion. Under the pillow is the main layer of backfill, consisting of anti-capillary rubble.

External insulation along the perimeter consists of a vertical plinth cladding and an insulated scaffold. There are no original engineering solutions that are peculiar exclusively to houses on a pile foundation. Everything is done according to the principle of eliminating cold bridges. There should be no gaps or gaps between the insulating layers of the wall, plinth and scaffold. In this case, overlap connections are preferable to butt contacts.

For lining the basement with insulation and finishing, it is necessary to form a crate. For this purpose, piles are tied. The strapping may consist of rolled metal and wooden moldings. The idea that this measure is an additional factor in increasing the rigidity of the pile foundation is devoid of real grounds. Sometimes, instead of cladding EPPS along the crate, laying in half a brick is performed. But they try to rest it from below not in the blind area, but in the channel, which is welded to the bottom of the piles.

The option with a high base is different in that the floor slab does not rest on the ground, but on the grillage. In this case, it is acceptable to perform both external and internal insulation of the slab. In any case, it makes sense to exclude the cold bridge from overlapping on piles through the grillage. For this, a thermal break in the horizontal plane is used. It can be performed by mounting the EPS between the grillage and the belt of additional foundation blocks, on which the floor is already directly supported.

Insulation of a pile foundation with a wooden beam ceiling

When designing a house on a foundation of metal screw piles, in most cases they try to minimize the load on the ground. To do this, use a beam ceiling made of a special wooden beam. How to insulate the foundation screw piles if wooden structures are used at the base of the floor? Firstly, for the thermal insulation of the floor, a structural "cellular" relief is used, formed by beams and lags. Secondly, in order to reduce the effect of condensate on the beams, the basement is insulated according to a different scheme than when using concrete floors.

Flush with the bottom of the beams, a beam with an approximate section of 50 × 50 is attached along them. This molding is a support for the "subfloor" - boards on which sheet waterproofing and the first layer of insulation are laid out. The most commonly used mineral wool. On top of the beams, logs are attached perpendicular to them. A second layer of thermal insulation is laid between the lags.

When arranging the horizontal insulation of the basement, they try to maintain a ventilated gap between the cladding and the scaffold. This is done in order to increase the service life of wooden beam ceilings.

Yes, this measure reduces the energy efficiency of the house, but the only alternative to it is the use of breathing room. It is allowed to keep the vents closed during frosts. Sheet waterproofing, located between the crate and horizontal insulation, goes below the cladding and bends in such a way as to direct rainwater runoff to the blind area.

The choice of finishes for the insulated basement

From a technological point of view, it is permissible to use all types of linings and finishes. It can be plaster, and decorative clinker, and lining of various types. Some XPS collections come pre-finished, reducing costs and speeding up work.

Insulation of the pile foundation with decorative EPPS boards

If we talk about the aesthetic side, then using the imitation of any materials, one should think about naturalness. For example, is it worth using clinker bricks as a plinth cladding for a house made of wooden beams?

If we turn to tradition, then during the mass wooden housing construction, a stone base was used much more often. Today it is much more logical to use special XPS slabs imitating masonry when building cottages from a bar on a screw foundation.

Conclusion

How to achieve maximum energy saving and reliability of the building, insulate the pile foundation, and even achieve the maximum possible resource of the house? To do this, you should first of all carry out a complete design of the house and foundation before construction, and not "solve problems as they arise." When using any typical thermal insulation design solution, be guided by two main principles: the elimination of cold bridges and the provision of acceptable operating conditions for the specific materials used.

Pile foundation, how to insulate, what materials to use for this. And let's start with the question: what is a pile screw foundation and why it needs to be insulated.

The basis of the house, made using metal piles twisted into the ground, is called pile screw foundation. This technology has been used for a long time, only slightly changed over time. For example, earlier, wooden poles impregnated with various anti-corrosion compounds could be used as piles. This was necessary to increase the service life of the structure.

Technology developed primarily for areas with swampy terrain or on heaving soils with unstable soil. The advantage of using a pile foundation is that the weight of the house is transferred through the piles to the lower soil layers, which are much denser than the upper ones. Thus, the risk of destruction of the building is minimized.

At present, to organize the foundation for this technology piles are used, at the end of which there are blades, resembling a thread on a self-tapping screw, it is for this reason that the foundation is called pile-screw. For the installation of such piles, special equipment can be used or they are twisted by hand.

The screw foundation can be classified according to the height of the grillage. The grillage is the first crown of the foundation, which rests directly on the piles, in some cases, it is also called the strapping.

Rostverk happens:

- Short, is installed below ground level, i.e. the pile is completely in the ground. According to this principle, a pile-strip foundation is arranged, which outwardly cannot be distinguished from a conventional strip foundation.

- High when the grillage is at a certain distance from the surface of the earth.

- Intermediate, in this case, the grillage is located on the very surface of the earth.

The answer to the question of why it is necessary to insulate the foundation on screw piles is that the space under the floor of the building is blown by the wind and no matter how the floor is insulated, it will not be as effective as if it was used together with insulation screw foundation.

An insulated foundation is a guarantee of underfloor heating and significant savings on heating.

Insulation of a pile grillage foundation with a low grillage level

Warming of the strip-pile foundation can be carried out in the same way as the usual strip foundation

due to the fact that it also goes deep into the ground and is made of reinforced concrete. This means that it is possible to use both sheet insulation for a pile foundation, and loose, and additionally insulate the structure with a warm blind area.

The insulation of the pile foundation grillage should begin with the marking and preparation of a trench with a width slightly more than the thickness of the insulation, a depth of 5-10 cm below the location of the bearing platform of the piles under the foundation.

At the next stage, it is necessary to clean the surface of the base and mount the insulation from moisture penetration, after which you can proceed with the installation of the insulation. To do this, you will need to have fasteners, mounting foam or other adhesive composition. Dowels for insulating materials are optimally suited as fasteners, or they are also “mushrooms” in the slang of installers.

Do-it-yourself insulation and finishing of the pile foundation

If necessary, and at the same time ennoble appearance plinth, you can apply the technology of insulation using bulk materials, together with plinth thermal panels.

The algorithm for this type of insulation is as follows:

- A trench is being prepared with a depth just below the pile pad and a width of 0.5 to 1 meter.

- Sand filling is being done.

- The trench is filled with insulation, a little short of the ground level, 5-10 cm is enough.

- Thermal panels are installed, they need to be deepened a little into loose insulation and secured with dowels.

- The blind area is poured.

Insulation of a pile foundation with an intermediate grillage

Insulation of this type of foundation is best done using thermal panels, since it is not necessary to significantly deepen the insulation into the soil. Thermal panels can be mounted both directly on the surface of the foundation, and on a pre-prepared crate.

Insulation of the basement of a pile screw foundation with a high grillage

A pile-screw foundation with a high grillage is the most common foundation of this type. Depending on the design, the grillage can be at different heights. At the same time, it is simply necessary to protect and insulate the space under the house. For this, technology is used to create false base.

Such a plinth can be made of brickwork, or using a wooden frame on which the insulation is mounted.

False brick plinth

The organization of such a basement for a house on a pile-screw foundation is not the most popular way to solve the problem. Firstly, brickwork turns out to be quite expensive, due to the fact that it is necessary to use facing bricks, cement, crushed stone and sand to make a pillow.

If you save on brick and use a cheaper one, then you will have to spend money on exterior decoration. Secondly, to hide the piles, you need to take out the brickwork so that they remain inside, which is not always possible to do.

The process itself looks like this:

- A trench is being prepared for the arrangement of a sand cushion, its average depth is about 20 cm.

- Crushed stone is poured and rammed, then sand.

Tip: for better compaction of the sand cushion, it can be poured with plenty of water and allowed to dry before laying.

- Brick is being laid. Masonry is used with an offset of half a brick, i.e. standard.

After the masonry is ready, it need to insulate the sides. To do this, it is more convenient to use sheet heaters. It can be polystyrene, or analogues. Insulation with expanded clay will require additional costs for the installation of formwork. One of the best options, this is applied from the inside of such a base, it will reliably protect the structure from the penetration of cold.

Insulation of the base of the pile foundation

Panel plinth or it can also be called a frame, which will reflect its essence much more fully, it is made according to the following scheme:

- Is being done double binding of all piles from the outside. With a high height of the grillage, the number of turns can be increased. The binding can be both metal and wooden. Metal, as a rule, is fixed for welding, this is the most popular way, as for wood, you can weld guide corners on piles and fix the strapping with wood screws. The second option is to use metal clamps.

- At the next stage, you can install thermal panels, or sheet insulation. If it is planned to insulate the base with the help, then the strapping must be sewn up with tessellate, after which the insulation should be sprayed on both sides.

When using non-insulated panels to create a plinth, it can be covered with soil from the inside, but it is better to use expanded clay for these purposes. At the same time, do not forget about the waterproofing of the grillage.

When using non-insulated panels to create a plinth, it can be covered with soil from the inside, but it is better to use expanded clay for these purposes. At the same time, do not forget about the waterproofing of the grillage.

Benefits of a panel plinth obvious, this is the simplicity of design, speed of installation, a large number of options for insulation, both from the inside and from the inside.

If you plan to independently manufacture a false base, you will need the following tools and skills to work with them:

- welding machine for welding fasteners to piles;

- "Bulgarian" for cutting metal corners;

- drill for drilling corners;

- a screwdriver for mounting self-tapping screws that fasten the insulation;

- building level for leveling the strapping along the horizon;

- chainsaw for cutting wood trim.

conclusions

The pile-screw foundation with a high grillage is popular due to its low cost and high practicality. Its disadvantage is the ventilated underground space.

To protect the house from the penetration of cold and just to give it beauty, the technology of creating a false base is used. You can make it with the help of insulated brickwork, but it is better to use the technology of an insulated panel base. Compared with brickwork, the panel plinth is much cheaper and more efficient.

Useful video

How to close the basement of a pile foundation with a brick:

In contact with

Despite the lightness and reliability of pile-grillage foundations, they have one significant drawback - the presence of open space under the floor of the first floor of the building. Also, a monolithic grillage can lie directly on the ground or be shallow.

And due to the constant impact of groundwater, over time, the material of the grillage will collapse, and the building will shrink. In order to preserve the integrity of the structure as long as possible, it must be carefully waterproofed and insulated. And there is a whole technology for warming pile-grillage foundations, which every builder should know about.

Insulation technologies for pile-grillage foundations

At the moment, there are a large number of different technologies for the insulation of grillages, ranging from the use of polymeric materials to the blind area. But here the key task is to choose the optimal technology that is suitable for a particular foundation and takes into account not only the climatic conditions of a given territory, but also the properties of the soil and the height of water ground horizons. Therefore, the popular technologies for warming pile-grillage foundations are as follows:

- Adding expanded clay to the sinuses;

- Installation of modern polymeric heaters;

- blind area device;

- Combining all three methods and using them simultaneously.

It is clear that all these are traditional methods of insulation that are suitable in one climatic region, but cannot be used in another. The advantage of such methods is that they are relatively simple and easy to implement. And materials for insulation and waterproofing are available commercially. But the key drawback of these technologies is far from excellent efficiency in conditions of high groundwater content, as well as the unpresentable appearance of the basement. It is clear that the blind area can eliminate such shortcomings, but this is more a waterproofing of the foundation than a decorative design.

What is a blind area and why is it needed

The blind area is a special waterproofing of the outer surface of the foundation, designed to drain rainwater from the basement towards the drainage system. It is made of sand, expanded clay and clay, the upper ball is concreted with some slope to the side. As a rule, the blind area has both the characteristics of waterproofing and insulation, and also has a decorative purpose. Not surprisingly, it can be found near the basements of old houses, where rainwater drainage plays a key role.

As a heater, the blind area is also used, only granulated expanded clay is used inside, which acts as a backfill near the outer surface of the tape grillage.

Insulation of the pile-grillage base from the outside

As a rule, the design of a pile-grillage foundation provides only external insulation and waterproofing. The side faces here serve as a basement and it is just insulated. For this you can use:

- A layer of bitumen that covers the side faces of the grillage. This is good waterproofing. After all, bitumen forms a strong and reliable layer of protection.

- Expanded polystyrene or polystyrene. This is a polymer thermal insulation, glued to bitumen or directly to the leveled surface of the grillage.

- Then all seams must be sealed with mounting foam to prevent the formation of cold bridges. But when using foam plastic in several layers, it is not advisable to do this, because foam plastic sheets have a contour shape and are attached to each other.

- As an additional thermal insulation, a reinforcing steel mesh is used. It is used to protect the insulation from rodents, and also as a basis for further plastering of the basement.

- As soon as the glue under the plates dries completely and the mesh is tightened. From above it is necessary to cover the structure with plaster.

There is also an alternative to such insulation technology. This is the construction of the basement belt type. In most cases, it is installed around the beam grillage on the outside, forming a "warm masonry".

But the insulation of such a structure in some cases may be more expensive in the end than the thermal insulation of the main foundation.

Insulation of pile-screw bases

The technology of insulation of pile-screw bases practically does not differ from the insulation of tape grillages, because they are present everywhere. But there is one feature here - this is the possibility of warming only at the level of the grillage, because technically it is practically impossible to insulate piles. In such cases, a strip plinth of concrete blocks or bricks is erected around the perimeter of the base, and the interior space is filled with expanded clay or soil. The technology itself is not complicated, but rather time-consuming and requires appropriate knowledge.

- First of all, it is necessary to waterproof all sections of the foundation and provide for a drainage system under the blind area. All open parts of the grillage are covered with a layer of bitumen or roofing felt, you can also use a liquid waterproofing agent, but it is more expensive than bitumen, although it is more effective.

- Then they make waterproofing of the vertical sections of the base, and both of its sides. The insulation technology is the same as for the insulation of the grillage from the outside, only here you also need to waterproof the piles. The upper edge of the piles is covered with bitumen or roofing material, and the well is made larger in diameter than the diameter of the pile.

- After installation of all piles, a bulk cushion is formed. This pillow should be between the zero and lower levels of the base, the pillow can be made from building sand with expanded clay and rammed.

Features of insulation of grillage bases

Despite the fact that now on the building materials market you can pick up a variety of heaters of polymeric and mineral origin, people often adhere to traditional technologies.

There are several reasons for this: traditions, the cost of materials, the ability to do everything yourself, as well as durability. After all, even the pavement, made correctly with an optimal slope and waterproofing of the connection of the concrete platform with the plinth, provides excellent protection against rainwater. And for thermal insulation, cheap and lightweight foam is used.

But polystyrene is not suitable for soils that are characterized by high humidity. Here it is better to use waterproof heaters, because only they are able to withstand prolonged exposure to even aggressive groundwater.

Any technology for insulating pile-grillage foundations has its positive and negative sides. Here the cost of materials and work, the shape and features of the foundation, the factor of quality and durability are noted. Therefore, you need to decide on your own how and with what to insulate such a foundation without much damage to the wallet and loss of quality and reliability of the foundation.

The pile foundation must be insulated in accordance with all existing regulatory requirements. If we consider the installation features of this foundation, in most cases it is mounted on heaving soil. Such soils are typical for unstable climatic conditions, so there is a need for thermal insulation. This action will favorably affect the health of the residents of the house, as it will ensure the circulation of warm air in the space between the ground and the foundation. In our article we will discuss all the features and nuances of such works.

Features of the foundation device

The foundation for a stilt house is built on a special soil - heaving, which is affected by seasonal climate fluctuations. For this reason, it is necessary to tighten the base structure. This can be done by connecting piles to each other with special elements - grillages. The following materials can be used as this part:

- Metal beams;

- Wooden block;

- Bulkheads made of bricks or concrete.

Attention! The pile-grillage foundation is by far the most used and versatile foundation for a house.

Everyone knows that the pile type of structure has a fairly cold floor, which can reach sub-zero temperatures in winter. It is for this reason that there is a sharp need for its warming. Today, there are a huge number of ways to accomplish this task. The most popular option is to perform insulation outside the house. This process is based on the construction of the basement.

Reasons for thermal insulation

There are a number of reasons that indicate that insulation is required not only for the building, but also for its foundation. Consider them:

- One of the main reasons is the need for heat in the building. Thermal insulation creates an additional flow of heat in the room.

- If the basement is insulated, it will add space for the house, which can be used in household activities;

- In the case of thermal insulation of the basement, you will get rid of the condensate that appears with the advent of spring.

Necessary materials

When performing installation work on the construction of a house or other building object, the activities of a specialist must rely on his personal experience. The debatable question of this process remains what kind of material to use.

The pile-screw foundation can be insulated with expanded clay, polystyrene or mineral wool. It is worth noting that this action for grillage should be provided at the stage of installation of piles. In cases where cotton wool is used, it must be waterproofed.

Attention! For construction sites on heaving soils, moisture protection is a must.

Thermal insulation options

The process of warming a house is quite simple to perform, so it is easy to reproduce with your own hands. There are a huge number of materials and methods for performing this task. All thermal insulation options can be grouped into three groups:

- Warming outside the house. The method involves building small walls and insulating them on both sides.

- Floor insulation. The floor also requires more heat, but this option is used in areas with a risk of flooding. The most popular way to accomplish this process is to insulate it from the outside, which is less expensive, but also has a lower level of productivity.

- Complete home insulation system. The process includes: floor insulation, foundation walls, as well as the performance of these works inside and outside the premises.

Process steps

It should be noted that the preliminary task is to perform calculations and select all necessary materials. When performing thermal insulation, it is very important to simultaneously perform an action on the outside of the floor. Considering this process, we can say that it is enough to complete it with the following main steps:

- Insulation of piles made of metal or concrete;

- Construction of a frame for the basement;

- Installation of hydro- and thermal insulation materials inside the basement space;

- Filling with expanded clay space at a given level;

- Thermal insulation of the floor outside the basement of the house;

- Installation work on the creation of decorative panels and their finishing.

Let's look at each stage separately.

Works for waterproofing

This process for the foundation must be carried out to protect the wooden material of the house and the piles. This will ensure the strength and durability of the structural elements. Water is also dangerous for metal, which is susceptible to corrosion, so it must also be isolated. To do this, you can use roofing material for the roof, which must be mounted at the joints between the wall and the base. To protect them, they need to be wrapped with roofing material on a surface smeared with mastic - this will improve its contact with the metal.

Before you start warming the floor, you need to treat the entire surface with an antiseptic, which will protect the wood from mold and insects. It is worth considering that it is additionally better to process the frame elements with a fire-fighting agent. Modern impregnations give the tree the ability not to burn, but to smolder, which will give time to save your home in case of a fire.

Attention! There are expensive substances in liquid or membrane materials that are able to repel moisture.

We are building a plinth

After the waterproofing of the grillage is completed, you can begin to sheathe and create a basement level. The choice of method for its construction depends on the type of soil on the site and the individual preferences of the customer. The most popular of them is considered to be a plinth made of bricks. To implement this method, an additional base is needed, which is why they dig a ditch for reinforcement. The depth for such a foundation can be up to 20 cm.

The trench must be filled with mortar and left to dry - this will create a belt of support for the walls. The indicator of wall thickness is not important, it is enough to adhere to laying in half a brick. It is necessary to take into account the mobility of the soil, which requires additional reinforcement.

The benefits of thermal insulation

Despite the high popularity of the pile foundation, its huge disadvantage is the need for insulation. But, the implementation of thermal insulation for the foundation gives it a large number of advantages:

- High temperature flooring in the house;

- Proper implementation of waterproofing and insulation processes will make it possible to improve the appearance of the building;

- If moisture protection is performed, then the amount of water entering the building is reduced;

- Beneficial effect on the health of residents;

- Protects construction materials from corrosion and other negative influences;

- Extends the life cycle of the house.

The process of thermal insulation for the foundation of a building is a very important and necessary construction stage. It is worth considering that if you live in an area with a constant positive temperature and low humidity, then insulation will not be useful to you. In other cases, it is necessary. The method by which you can perform this action, you can choose according to your liking.