Special attention is always paid to the construction of a highly reliable foundation for a house under construction. This is not surprising - the duration of the trouble-free operation of the building, and, by and large, the safety of living in it always directly depends on the strength and stability of the base. When creating a foundation, simplification of established construction technologies, ignoring requirements in order to speed up the process or reduce the cost of the overall estimate, and the use of low-grade materials should be categorically excluded.

Paradoxical as it may sound, but a powerful foundation structure, created according to all the rules and having a solid margin of safety, still remains very vulnerable to various external influences, and primarily to moisture. Protecting the base of a building from the damaging effects of water is one of the key tasks, the importance of which, unfortunately, some novice builders simply overlook. There are many different ways solutions to this problem, and in the field of individual construction, it has won the greatest distribution with roll materials. This technology will be discussed in this publication.

Why should special attention be paid to the issues of waterproofing the foundation?

Before proceeding directly to the consideration of foundation waterproofing technologies, it seems necessary to give the novice master an explanation of why this stage of construction is so important, and what consequences the absence or insufficient protection of the base of the house from the effects of moisture can lead to.

To begin with, let's see in what layers of soil water can be located in one state or another.

- The upper layers of the soil, including fertile soil, always contain a certain amount of moisture, which penetrates there due to atmospheric precipitation, snow melting or in other ways - for example, direct spillage of water during irrigation of the site, when washing a car, in case of an accident on the water supply system and in other similar situations.

It is clear that the concentration of moisture in the upper, so-called filtration layers of the soil is a constantly changing value, which is interconnected with the established weather conditions, the season, normal or abnormal amount of precipitation, etc. But it also happens that if a water-resistant clay layer is located close enough to its surface in the soil, then this moisture is collected in a fairly stable aquifer, which is often called a water-bearing horizon. And such a top water is already capable of bringing a lot of additional trouble, since, in addition to capillary penetration into the walls of the foundation, it is also capable of exerting a certain dynamic effect.

To reduce the impact of moisture in the upper layers of the soil, a properly planned and constructed storm sewer system is essential.

The stormwater storm, the importance of which some simply forget ...

Collect and drain water that has fallen by rain or formed during the melting of snow in spring, prevent erosion of building structures, get rid of constant puddles in the yard, protect the site from waterlogging - all these problems should be solved, the independent creation of which is devoted to a separate publication of our portal.

- All layers always contain a certain amount of water, which is retained in them due to the capillary qualities of the soil. Here we can already talk about a fairly stable concentration of moisture, which is not particularly influenced by external changes in the weather or season.

This state of water does not have a dynamic effect on the walls of the foundation - everything is limited to infiltration into the thickness of the material. Usually, a not too thick but durable waterproof layer of waterproofing is sufficient to counteract this. True, for areas with an increased saturation of soil with moisture, for marshy areas, it will be impossible to do without the creation of a drainage sewerage system.

Areas with high soil moisture require a drainage system!

If the soil at the construction site is clearly waterlogged, or aquifers are located close to the surface, then a system is required to constantly remove excess moisture to safe places. How - read in a special publication of our portal.

- Finally, there may be aquifers close to the surface on the site - this already depends on the characteristics of a particular area. The depth of their occurrence is different, but often they are located only 5 ÷ 7 meters from the earth's surface. The degree of their occupancy is a variable value, also depending on external current conditions. A clear proof of this is the fluctuation of the water level in the well.

This state of affairs requires maximum protection of the foundation when it is deeply buried, that is, a well-thought-out multi-layer waterproofing of all structural elements. In addition, an efficient drainage system is extremely important.

Now a few words about how moisture can negatively affect the structure of the foundation.

- From school we all know the chemical formula of water, but what falls out with atmospheric precipitation or penetrates to the foundation through the soil is very far from the notorious "Ash-Two-O". Moisture can literally be oversaturated with aggressive chemical compounds of organic or mineral nature - industrial emissions, car exhaust, spilled oil products, agricultural chemicals and much more are dissolved in it.

Such a "chemical attack" on concrete does not pass without leaving a trace - its structure can change, which leads to violations crystal lattice, the occurrence of erosion processes, the gradual shedding of the outer layers of the reinforced concrete structure.

- Where erosion and shedding of concrete began, the reinforcement of the structure will also be exposed over time. And then metal corrosion will take over for its "dirty deed". Moreover, this is fraught not only with the loss of strength of the reinforcing frame itself. In place of the reinforcing rods "eaten" by corrosion, internal cavities are formed, which sharply reduce the strength properties of the foundation, and ultimately lead to the chipping of large fragments of the reinforced concrete structure.

- Moisture penetrating into large and small cracks or even simply absorbing into the pores of concrete has a powerful destructive effect, which manifests itself when freezing. Expanding many times in volume upon transition to solid state of aggregation, water is capable of literally tearing apart seemingly powerful, invulnerable to external influences, concrete structures or walls lined with piece materials.

- Finally, in the presence of aquifers or closely spaced aquifers, a washout effect cannot be ruled out. Constant dynamic contact of foundation structures, even with perfectly clean water, leads to surface disturbances - cavities or cavities are washed out, which then become centers of centers of concrete erosion and corrosion of the reinforcing frame.

So, there are more than enough reasons for carrying out high-quality waterproofing work. Now let's see how you can accomplish this.

What is being done to protect the foundation from the destructive effects of moisture?

To prevent the destructive effect of soil and atmospheric moisture on the structure of the foundation, a number of measures are taken during construction. These include the following:

- The base of the building is erected from ready-made materials, additional hydrophobic qualities are given.

- On the walls of the foundation, vertical (along their entire height) and horizontal, moisture-impermeable coatings are created.

- A subsiding horizontal waterproofing is created between the foundation and the walls of the building erected on its basis - to prevent the capillary propagation of moisture upward through the wall material.

- It is ensured by the creation of drainage and storm sewers, a constant effective removal of excess moisture from the foundation of the house.

- Measures are being taken to thermally insulate the foundation structure and the strip of blind areas around it.

- The waterproofing and insulation layer itself is provided with reliable protection against mechanical damage.

- Efficient air ventilation is provided for basements or basements.

There are several varieties for this area of construction. Not all of them are equally capable of withstanding the external pressure of moisture, there are significant differences in application technology, and there may be a great difference in the price segment.

The table below compares some of the main types of foundation waterproofing in terms of their ability to withstand different types of ground moisture and in strength parameters.

| The type of waterproofing and the materials used for it | Cracking resistance | The effectiveness of the created protection against various types of soil moisture | Room class | |||||

|---|---|---|---|---|---|---|---|---|

| top water | soil moisture | aquifer | I | II | III | IV | ||

| Roll-on waterproofing using modern bitumen membranes on a polyester or fiberglass base | high | + | + | + | + | + | + | - |

| Waterproofing using polymer waterproof membranes | high | + | + | + | + | + | + | + |

| Coating waterproofing using polymer or bitumen-polymer mastics | average | + | + | + | + | + | + | - |

| Flexible coating waterproofing using polymer-cement compositions | average | + | - | + | + | + | - | - |

| Rigid waterproofing coating using cement-based compounds. | low | + | - | + | + | + | - | - |

| Penetrating waterproofing, dramatically increasing the hydrophobic properties of concrete | low | + | + | + | + | + | + | - |

Probably, one clarification should be made regarding the last columns of the table - the classes of the basement or basement rooms:

- The first class refers to premises for which there are no special requirements for waterproofing. That is, wet spots on the walls, and even small leaks, are permissible there, but the use of any electrical lighting devices and sockets is completely excluded. Naturally, hunters will not be able to leave such premises in residential construction.

- The second class is utility or technical rooms, with a wall thickness of at least 200 mm, where humid vapors are allowed (they must be removed by a mandatory ventilation system), but there should be no damp spots. Under such conditions, the room can be equipped with electrical wiring.

- The third class is the optimal standard for a residential building, that is, it is advisable to focus on it when building on your own. The penetration of moisture is completely excluded, the work of natural or forced ventilation is ensured, there are no restrictions on the equipment of the premises. In this case, the thickness of the walls is at least 250 mm.

- In private construction, as a rule, they do not encounter the fourth class of premises, in which a special microclimate must be provided and strictly regulated indicators of humidity and temperature must be maintained.

If you analyze the table, and at the same time take into account the cost of various materials, then one of the most optimal solutions becomes the use of a roll-on waterproofing on a bitumen basis - it fully corresponds to class III premises, is resistant to cracking and is able to protect the foundation from the effects of any type of groundwater ... And in order to achieve the best indicator of reliability, it is often combined with polymer-bitumen-based coating insulation.

Brief overview of bitumen-based roll materials

The products of the Russian company TechnoNikol can serve as a kind of standard for the quality and effectiveness of waterproofing for foundations. Its product range includes a number of bitumen-based roll materials that are excellent for these purposes. And they differ in their intended purpose, the thickness of the layer to be created, the peculiarities of the technology of application on the surface of building structures, durability, and, naturally, according to the price criterion. That is, the consumer has the opportunity to choose the material that is optimal for his conditions.

Prices for "Bikrost CCI"

bikrost tpp

The most popular types of rolled waterproofing materials of this brand are shown in the table:

| Roll waterproofing name | Illustration | Brief description of material features | Approximate price level |

|---|---|---|---|

| "Bikrost CCI" | One of the budget options. It is obtained by applying a bituminous substance with modifying additives to a glass-cloth base. The technology of application to the surface is deposition. The outer coating of this type of material (TPP) is a polymer film. The guaranteed service life is short - about 5-7 years, which is certainly not enough for a foundation. Operating temperature range - from -3 to +80 ºС. The thickness of the resulting insulation is 3 mm. It is produced in rolls 1 m wide and 15 m long. | 65 ÷ 70 rubles / m² | |

| "Linokrom EPP" | The material can also be considered "budgetary" although the durability of the created waterproofing is already higher, and is estimated at 7-10 years. The basis is polyester fibers. Excellent adhesion to concrete and metal surfaces. The outer protective coating is a polymer film. Release form - rolls 15 × 1 m. Operating temperature range - from -30 to +80 ºС. | 65 ÷ 70 rubles / m² | |

| "Bikroelast CCI" | Waterproofing material based on polyester or fiberglass. The outer coating is a polymer film. The service life is estimated at 15 years or more. Installation method - fusing on the prepared foundation surface. | 75 ÷ 80 rubles / m² | |

| "Uniflex CCI" | Roll-up waterproofing material of business class on a fiberglass basis. Installation technology - fusion. The thickness of the layer to be created is 2.8 mm. The outer coating is a polymer film. The service life is estimated at 15 ÷ 20 years. Operating temperature range - from -30 to +95 ºС. | 95 ÷ 100 rubles / m² | |

| "Bipol Standard 3.0 CCI" | Roll waterproofing of the "standard" class with a service life of up to 10 ÷ 15 years. The outer coating is a polymer film, the base is fiberglass. Application method - fusing with a gas torch. Release form - rolls 15 × 1 m. | 75 ÷ 85 rubles / m² | |

| "Stekloizol HPP 2.5" | Economy class waterproofing with a guaranteed service life of 5 ÷ 7 years. The basis is fiberglass, the top coating is a polymer film. Installation technology - "cold" gluing on the applied layer of bitumen mastic. Operating temperature range - from -20 to +80 ºС. Release form - rolls 10 × 1 m. One of the most affordable materials for the price criterion. It is recommended to create at least two layers of insulation. | 30 ÷ 40 rubles / m² | |

| Technoelast EPP | Premium waterproofing material. The base is polyester fibers, the outer coating is a polymer film. The thickness of the waterproofing layer to be created is 4 mm. The guaranteed service life of waterproofing is 25 ÷ 30 years, and the total service life is estimated at 40 years or more. The ability to withstand the constant dynamic pressure of groundwater. Application technology - deposition with a gas torch. Operating temperature range - from -30 to +100 ºС. Release form - rolls 10 × 1 m. | 135 ÷ 140 rubles / m² | |

| Technoelastmost B | Premium roll material with increased durability and reliability. The thickness of the layer to be created is 5 mm. The outer surface is coated with fine-grained sand, which creates additional protection against mechanical damage. It is used for waterproofing powerful reinforced concrete structures and deep foundations. Installation technology - fusion. The service life is estimated at 40 years or more. Operating temperature range - from -30 to +100 ºС. Release form - rolls 8 × 1 m. | 220 rubles / m² | |

| Technoelast ALFA | Premium roll material, recommended for use as a single-layer or multi-layer (for the outer layer) waterproofing in regions with an unfavorable environmental atmosphere. The base is a polyester fabric and metal foil, which acts as a gas insulation, not allowing inert gases (including radon) to pass through. Installation technology - fusion. The service life in the buried part of the foundation is more than 60 years. Operating temperature range - from -30 to +100 ºС. Release form - rolls 10 × 1 m. | RUB 250 / m² | |

| Technoelast GREEN | Roll material used in conditions where additional protection from the root system of plants is needed. Mechanical and chemical "barriers" prevent root damage to the waterproofing layer. The thickness of the coating to be created is 4 mm. Installation technology - fusion. The service life is estimated at 25-30 years or more. Operating temperature range - from -30 to +100 ºС. Release form - rolls 10 × 1 m. | 230 rubles / m² | |

| "Technoelast BARRIER (BO)" | A baseless waterproofing material of premium class, especially convenient in those cases when "hot" welding works are impossible or impractical. Installation on a surface prepared by a primer using a self-adhesive layer, which is covered with a polymer protective film before use. The thickness of the created single-layer coating is 1.5 mm. High elasticity and excellent adhesion to prepared and primed surfaces. Service life - 40 years or more. Operating temperature range - from -30 to +85 ºС. Release form - rolls 20 × 1 m. In addition, in some cases), for example, when creating amplification areas), it is more convenient to use the material of a reduced format "Technoelast BARRIER BO Mini" - 0.2 × 20 or 0.25 × 20 m. | 150 ÷ 160 rubles / m² |

As you can see from the table, materials differ in the thickness of the created layer. But what thickness should the finished waterproofing be? You can focus on the following indicators:

- When working on a shallow foundation, up to 3 meters deep, 2 mm waterproofing is sufficient (of course, with reliable sealing of all overlaps of the material and creating protection against mechanical damage from the soil). Thus, you can use a single-layer installation, but with mandatory reinforcement at the vulnerable points (this will be discussed below). True, if an economy-class material is used, then it is still better not to be stingy, but to perform a two-layer waterproofing, and with the obligatory displacement of the seams between the sheets, by about half the width of the web of the rolled material.

- For deep foundations, with a footing depth of 3 to 5 meters, the thickness of the layer to be created should be in the range from 4 to 8 mm (depending on the specific characteristics of the soil at the construction site).

- And, finally, in the case of deepening the sole into the ground below a 5-meter level, the waterproofing should be 8 mm or more. In private construction, such foundations are usually not used, so this information is just for information.

Basic technological rules for waterproofing a foundation with rolled bituminous materials

General foundation waterproofing schemes

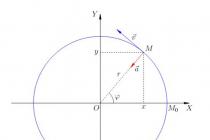

Foundation waterproofing is divided into horizontal and vertical. The diagrams below will show the typical arrangement of such waterproofing layers on two types of foundations - on and on a monolithic slab.

On the selected and carefully compacted soil (pos. 1), a sand and gravel pad (pos. 2) is poured. In addition, a so-called concrete preparation (pos. 2) can be carried out on top of it (it is recommended) - a layer of about 50 mm thick from lean concrete is poured, which will become the basis for further pouring or laying the foundation tape.

Prices for Technoelast

Technoelast

This diagram shows a monolithic strip foundation- its prefabricated options are often used, but the essence of this changes slightly, there are only certain nuances.

A monolithic tape or slab (item 4), which will act as a sole, and sometimes also the base of the floor in the basement, as in this illustration, must be separated from the layer of concrete preparation by the "first tier" of roll waterproofing (item 3) so that exclude capillary absorption of moisture from below. In the shown variant, the sole and the tape (pos. 5) of the foundation are a monolithic structure. But in the event that the tape is poured separately from the sole, or it serves as the basis for laying foundation blocks, then another layer of horizontal waterproofing is usually provided - precisely along the upper end of the sole, between it and the tape.

The transition from the horizontal plane of the sole to the vertical strip must be softened. For this, a transition fillet is laid along the line of this inner corner (pos. 6).

Vertical waterproofing on the walls of the foundation tape (pos. 7) is fused or glued over its entire area onto a surface previously prepared and treated with a primer bitumen primer.

The horizontal surface on the top of the foundation strip is also waterproofed without fail (pos. 8). This horizontal layer becomes a reliable cut-off from the spread of capillary moisture from the ground to the walls of the future structure. This can be done by bending the provided excess roll vertical insulation, or separately, with cut strips, but with the obligatory condition of reliable sealing of the transition from the wall of the strip to its upper end.

The diagram additionally shows: a pipe of an annular drainage system (pos. 9), the importance of which was already mentioned above, backfilling of the foundation (pos. 10), which is carried out after the completion of work on its waterproofing and, if required, insulation, and a blind area around the base buildings (item 11).

Never forget about a quality blind area!

It performs by no means only a decorative function - its importance in ensuring the durability of the foundation, and therefore the entire building as a whole, cannot be overestimated! What are, and how to build them with your own hands - read in a special publication of our portal.

Now let's move on to the waterproofing scheme slab foundation:

In a dug-out pit on compacted soil (pos. 1), a sandy one is poured and carefully compacted (pos. 2). On top of it, a layer of gravel or gravel (pos. 4) is laid out and carefully rammed, which will also perform a certain waterproofing role - through such a layer, the capillary "suction" of moisture from below, from the side of the soil, sharply decreases. For greater reliability, the laid "pillows" are made of a kind of reinforcement, laying between them a layer of geotextile, for example, dornite (pos. 3).

Above is a layer of concrete preparation, at least 50 mm thick (item 5), which will level the base and become the base for the most important work with the foundation slab. And this layer already needs high-quality horizontal waterproofing (item 6), which will become a barrier that completely protects the foundation from moisture from below. The optimal solution for this is precisely the rolled bitumen-polymer waterproofing materials, with which the concrete preparation is completely, hermetically covered.

This illustration shows the insulated version of the foundation slab. In particular, extrusion slabs (item 7) are laid on top of the waterproofing, designed specifically for warming foundations and loaded floors. And only after that the reinforced foundation slab itself (pos. 9) of the calculated thickness is poured.

Pay attention - another layer of waterproofing was laid between the layer of thermal insulation material and the foundation slab (pos. 8). It has a slightly different purpose - it only prevents moisture and cement laitance from escaping from the poured concrete solution, thereby ensuring optimal maturation of concrete to a full set of branded strength. Here, to create a waterproofing barrier, it is quite possible to do with the most economical material, for example, use a dense polyethylene film with a thickness of at least 200 microns.

Well, the resulting slab itself is so far only the foundation from which both the erection of the walls of the building and the further equipment of the floors of the first or basement floor will be carried out. Before any of these operations, one more complex of waterproofing work is necessarily carried out - a continuous roll waterproofing is laid, which will eventually cover the entire slab, reliably protecting it from moisture penetration from above. In addition, measures are provided to insulate the vertical ends of the slab - as a rule, such measures are taken already during the insulation and finishing of the basement.

It should be noted that these options were shown only for example, but in fact, their variety is extremely large. But the basic rules are always followed:

- The first is to protect the underground part of the foundation in contact with the ground from the effects of ground moisture.

- The second is to provide for a "cut-off" between the foundation itself and any other structure of the house, which is built on its basis.

Technological techniques for laying roll-up waterproofing on a bitumen basis

Further, in the instruction tables, the main technological methods for performing waterproofing of the foundation will be considered. Particular attention is paid to difficult places that require additional strengthening, and which, unfortunately, some masters simply forget, or they deliberately ignore this issue, trying thereby to speed up the overall duration of the process and save material. If the work is planned to be carried out not independently, but with the involvement of a team, then this issue must be taken under control.

Performing horizontal waterproofing

| Illustration | |

|---|---|

| As a rule, waterproofing of the horizontal part of the foundation (with the exception of the upper end of the tape) is carried out according to the concrete preparation. Ideally, this should be done before the foundation strip soles are installed or before the strip is poured. An approximate diagram of the correct arrangement of waterproofing layers is shown in the diagram. 1 - concrete preparation; 2 - horizontal waterproofing from roll materials; 3 - Foundation wall, monolithic or made of blocks; 4 - transition fillet; 5 - section for strengthening waterproofing; 6 - vertical waterproofing of the foundation tape. Please note - with this approach, the horizontal waterproofing layer should extend beyond the boundaries of the future tape by at least 300 mm - in this area, the joint between the horizontal and vertical waterproofing will be sealed. |

| There is no point in starting work on an unprepared - dirty, dusty, uneven or even unstable surface. This means that the first step should always be an audit of the surface condition. There should be no cracks, potholes, concrete slugs, areas of instability or crumbling of material on it. If defects are detected, appropriate repair work is carried out. The magnitude of the difference in surface level should not exceed 5 mm per 2 running meters - this is checked by applying a long rule. |

| The surface must be free of any contamination that could interfere with the normal adhesion of the waterproofing layer to the substrate. This applies to dirt, oil stains, etc. It is imperative that dried cement milk and dust are carefully removed. Coarse dirt can be swept away with a broom ... |

| ... but for effective cleaning of fine dust, it is still better to use a powerful construction vacuum cleaner. |

| The next step is to prime the surface with a primer. However, before proceeding to this operation, it is necessary to make sure that the residual moisture content of the concrete does not exceed 4% by weight. The best way to carry out the test is to use a special moisture meter. It is clear that not everyone has such a tool, so you can use the "folk" method. To do this, a piece of plastic film with a size of 1000 × 1000 mm is spread on the surface of the concrete, and along the perimeter it is hermetically glued to the base using waterproof construction tape. The next morning it is necessary to check whether condensation drops have appeared on the film. |

| If the film is dry, you can proceed to priming the surface. For this, a special primer "TechnoNIKOL No. 01" or "No. 03" is usually used. |

| If the maturation period of the concrete preparation has completely expired, but the humidity remains elevated (traces of condensation are visible on the film), then it is possible to use the primer "TechnoNIKOL No. 04" for priming, since it is made on a water basis. |

| Before applying, the primer must be mixed. It is better to do this with an electric drill, installing a mixer attachment on it. The drill should be set to low speed. |

| The primer is applied abundantly, evenly, over the entire surface, without leaving "light" spots. On large areas, it is most convenient for these purposes to use a roller with a long nap, set on a long handle. |

| For difficult, hard-to-reach areas, it is advisable to use a paint brush with dense and stiff bristles. It should be noted that the manufacturer does not recommend mechanizing the priming process using certain types of sprayers - the quality is guaranteed only when the formulations are applied manually. |

| After covering the entire surface with a primer, it is allowed time to dry completely. It is unacceptable to carry out work on the fusion of roll waterproofing on a wet surface. Moreover, even within the same room or one site, it is impossible to simultaneously carry out priming and laying of waterproofing, or even other work related to open fire (for example, welding). It is not difficult to check the readiness of the primed surface - for this you just need to press a regular napkin against it. If a black mark remains on the napkin, it is too early to talk about the beginning of the next stage. |

| Only after there are no traces of the primer on the napkin, it is allowed to proceed to laying the rolled waterproofing material. |

| The equipment for material deposition is being prepared for operation. It includes a propane tank, gas heater, reducer, connecting hose. Preparation is carried out in strict accordance with the instructions, in compliance with all safety requirements. A working fire extinguisher must be available at the work site. Employees' hands should be protected with reliable gloves, clothing should not leave open areas of the body. |

| It is advisable to start the work with adjusting the starting sheet of roll waterproofing. It is unrolled to the required length, if necessary, cut to size. If there is such an opportunity, it is even recommended to let the material lie down for a while in the unfolded state. The canvas should be exposed exactly in the place where it will be fused - since we are talking about the starting sheet, then along the edge of the insulated area. |

| It is even better if you immediately try on several sheets by rolling them out, cutting them and immediately setting the necessary overlaps along the ends and sides. In this case, the following rules are observed: |

| The end overlap of adjacent canvases located in one line must be at least 150 mm. |

| The overlap on the lateral side between two adjacent strips of material is at least 100 mm. In the same case, if only one layer of waterproofing will be glued, it is recommended to increase this overlap to 120 mm. |

| In places where the end and side overlaps will intersect, T-seams are obtained. To ensure reliable sealing of such a connection, a corner with sides of 100 × 100 mm is cut diagonally on the sheet that is in the middle between the upper and lower ones. |

| It is imperative to make sure that these T-shaped seams go with a breakdown - the distance between adjacent ones must be at least 500 mm. |

| After trying on, the sheet of roll material is folded up again - for this, a cardboard sleeve or a piece of metal pipe is used. For the convenience of work, you can roll the roll not in one direction, but from both ends to the center. |

| Fusion of the material is started. For this, the back side with the logo printed on it heats up with the flame of a gas burner. Heating should be such that the protective film melts - this will be clearly visible from the deformation of the applied logo design. At the same time, the burner flame also heats up the concrete base to be waterproofed. |

| When heated, the burner is smoothly moved along the width of the roll. And only when melting is achieved throughout the entire area, rolling is performed so that the melted zone adheres tightly to the surface. In this case, each pressed area, as it rolls out, will "drive" a roll of molten bitumen in front of itself - this is how it should be, this just speaks of high-quality fusion. |

| On the Internet, you can find a lot of illustrations and videos in which the master rolls out the roll from himself, pushing it forward with his foot. Meanwhile - this is a violation of technology, and for two reasons at once. Firstly, an employee in this position cannot fully visually control the correctness and completeness of the material's protective film melting. And secondly, moving in shoes on a membrane softened by a flame, it is quite easy to damage its protective upper coating, which will lead to a decrease in the quality of waterproofing. |

| Roll out the roll must be carried out on oneself. To do this, you can use a metal hook, which is easy to make from trimming reinforcement, processing it after bending so that there are no sharp edges on the rod. |

| Another option is to make a loop from the same reinforcement or rigid wire, the edges of which are wound from the ends into the sleeve on which the roll material is wound. It is even easier to unfold a heated roll using such a device, simply by regularly pulling it towards you. |

| It is advisable to carry out the work with a partner who, immediately after the deployment of the next section to be welded, will roll it with a massive roller. Rolling is carried out from the center of the web to the edges, somewhat diagonally, that is, with a “herringbone” pattern, so as to completely exclude the presence of non-fused areas and air bubbles. Waves, folds, wrinkles are unacceptable. In such an operation, special attention is paid to the areas of end and side overlaps. |

| After rolling the edge zones, a small (about 5 ÷ 10 mm) bead of molten bitumen should protrude from under the deposited sheet - this indicates reliable sealing of the edge. In this order, work continues until the entire surface is covered with a continuous layer of waterproofing. |

| In a number of cases (this mainly depends on the hydrological characteristics of the foundation construction site), it is allowed to install horizontal waterproofing using free-laying technology, that is, without fusing over the entire area. The same method is used in the case when the waterproofing is performed not on a concrete base, but on a compacted sand and gravel "cushion". With this approach, the operation of preliminary priming of the surface is eliminated, the rolls are simply laid one by one on the surface, and at the same time the same linear parameters of the overlaps are observed. After precise adjustment of the two laid strips, the edge of the upper sheet is carefully lifted with a hook, the edge zone is heated with a gas burner, and only the overlap section is fused. Then this strip is necessarily rolled with a roller. True, when choosing a free-stacking technology, it should be remembered that one layer of roll material cannot be dispensed with. And at the same time, the second layer should be deposited in the same way as described above, that is, over its entire area. |

| In any case, when fusing the second (and subsequent, if necessary) layer, the direction of the canvases can be rotated 90 degrees. If the direction does not change, then the obligatory displacement of the longitudinal seams is made, at least by 300 mm, and optimally by half the width of the sheet, that is, by 500 mm. The rest of the overlap parameters and the distance between the seams are the same as when installing the first layer. |

| Another important nuance. In the case when a material with specific characteristics is used for multilayer waterproofing (for example, Technoelast Alpha or Technoelast Green), then it should be located on the side facing the ground. This means that with horizontal waterproofing, it becomes the first layer, and then it is covered on top with another material with standard characteristics. Looking ahead, we can immediately say that with vertical waterproofing, the picture changes to the opposite - first, the walls of the foundation are pasted over with ordinary material, and only the outer layer is installed with insulation with special characteristics. On the diagram, arrows and numbers show: 1 - reinforcement element - made of material with standard qualities. 2 - a layer of waterproofing made of a material with standard qualities. 3 - layers of roll material with specific qualities ("Alpha" or "Green"). |

| In the event that the production of hot work is impossible or impractical, you can use a self-adhesive version of roll waterproofing. In the "TechnoNIKOL" line, it is represented by the baseless material "Technoelast Barrier BO" |

| The surface preparation process is practically the same. Primer treatment is mandatory. The roll is rolled out, tried on, and then rolled from both sides to the center. During fitting and in the course of further work, all the parameters of the overlaps remain the same as in the case of welded waterproofing. |

| The adhesive layer on the underside of the web is covered with a plastic film. It is carefully trimmed and pushed across the entire width of the roll. |

| Then the film is carefully peeled off, releasing the self-adhesive layer, and the roll is being rolled out. |

| The work is best done together. One worker, removing the protective film, gradually rolls the roll towards himself. The second, moving over the already spread material, expels air bubbles with the help of a wide rigid plastic brush and ensures a snug fit of the material to the surface. Since the surface is treated with a primer, very good adhesion contact with the waterproofing to be laid is ensured. |

| In addition to this, all overlap sections are necessarily rolled with a heavy roller. |

| Now - a few words about the horizontal waterproofing of the basement part of the foundation (the upper end of the tape). It is forbidden to carry out any kind of construction work on the construction of walls until a cut-off is created from the possible spread of capillary moisture from below. Work begins, again, with a thorough cleaning and dust removal of the belt surface. Then a primer is prepared for work - the same as in the cases discussed above. |

| The primer is applied generously with a wide brush on all surfaces to be waterproofed. |

| While the primer is drying, you can prepare rolls of waterproofing material for work. They must be cut along the width of the foundation tape plus another 50 ÷ 70 mm of allowance on each side. You can cut a whole roll into strips of the required width without rolling it. To do this, you need an electric jigsaw with a long file. Gradually turning the roll, deep cuts are made along the marked circle. |

| In the center of the roll, these cuts will connect, and at the exit, mini-rolls of the same factory length, but with the width required for a specific work site, are obtained. |

| The cut roll is adjusted to the place of the future installation. It is rolled out, leveled, so that the strip of material does not "run away" from the direction of the line of the foundation strip. Then one edge can be immediately grabbed by fusion, thereby fixing the position of the canvas, and the roll can be rolled to this edge. |

| By the way, if the volume of work is not so large, and there is no way to rent a gas burner with a cylinder, then in this case you can use an ordinary gasoline blowtorch - many have such a tool in garages. It may not be so convenient to work, but for the surface of the foundation tape it is quite normal. But it is better not to count on a building hair dryer - its power will almost certainly not be enough for high-quality penetration of the protective layer of the material and for simultaneous heating of the concrete surface. |

| Further - almost everything is the same as in the previously considered cases. The roll is gradually rolled out with preliminary melting of the protective layer of waterproofing. It is recommended to immediately roll the weld material with a hand roller or a silicone roller. |

| Lateral overlaps are not expected here, but end overlaps are made in the same way - with an overlap of at least 150 mm. And at the points of intersection or abutment of the sides of the foundation tape, the overlap can be melted over the entire area of this intersection. |

| Excess material protruding along the edges of the tape is fused onto the vertical wall. If vertical waterproofing has already been carried out there, then you will get a reliable sealed overlap. |

| If the waterproofing and insulation of the basement are planned to be carried out later, then you can leave the overlap on the outer side of the foundation tape not glued. Or, which is probably even better, after melting this overlap, additionally melt on top of another strip of material of the required width. After being cut from the roll, this strip is first rolled out and leveled. |

| And then, just as before, it is fused onto the previously mounted layer of horizontal waterproofing tape. In the future, when the basement is insulated, this strip from above will overwhelm all layers, creating a reliable barrier against the penetration of atmospheric moisture and precipitation from above. |

Foundation vertical waterproofing

| Illustration | Brief description of the performed operation |

|---|---|

| If waterproofing will be carried out on a newly erected foundation, then usually a trench is immediately provided for the work. In the same case when it is required to waterproof old foundation, you will have to select the soil along the walls to the full depth, right down to the sole. The width of the trenches is made in such a way as to ensure the movement of workers and the safe performance of all technological operations by them, and, if necessary, also the installation of scaffolding, scaffolding or goats. |

| Work begins with cleaning the surfaces of the sole and walls of the foundation. It is necessary to thoroughly clean off all adhering dirt, remove the build-up of concrete or masonry mortar, and repair all cracks and crevices. |

| Dips in the surface that differ from the general plane of the wall by more than 5 mm by two running meters are unacceptable. If necessary, leveling is performed using a repair mortar. |

| Cleaning of surfaces is carried out first with scrapers (spatulas), then - with a stiff brush with metal bristles. All dirt that has fallen down is swept away, leaving a clean, dust-free sole surface. |

| If there are transitions from a horizontal to a vertical surface, for example, from concrete preparation to the sole and from the sole to the wall of the foundation, then a transition fillet is laid out there. It can be molded from a fast-setting mortar, since it does not perform any load-bearing function, and only serves to tightly adhere the waterproofing in places of sudden changes in direction, smoothing them out. Fillet dimensions are about 100 × 100 mm. |

| The fillet is laid out and leveled with a trowel or spatula. |

| The vertical surface of the foundation with the fillets lined will look something like this. |

| After the fillets have hardened, and provided that the residual moisture content of the concrete of the main surfaces of the foundation corresponds to the norm, the surface is primed with a primer. Moisture rates are the same as indicated in the previous table. The primer is thoroughly mixed and applied generously to the surface with a brush or long-handled roller. |

| All hard-to-reach areas, and especially internal corners and transitions, must be coated with a primer with a brush, so that there are no untreated areas. |

| After the primer has completely dried, they proceed to fusing the waterproofing material. At the same time, several important rules are observed: First, all work is carried out from the base of the foundation towards the basement part, so that each subsequent piece to be mounted overlaps the lower one. |

| Second, each of the welded sheets is also mounted from the bottom up. Otherwise, the molten tar will flow down the walls, fall on the hands, clothes and shoes of workers, and the quality of the waterproofing itself will sharply decrease. |

| Third, the cut fragment should not change direction from vertical to horizontal and vice versa more than two times (ideally, once is enough). That is, two or more sheets of material must be used in the "broken" areas. |

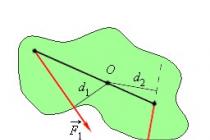

| Fourth, all difficult sections require the creation of a reinforcement belt. These include the transitions of a horizontal surface to a vertical one and vice versa, which is typical for foundations with a bottom, as well as all external and internal vertical corners. If a pipe of engineering communications passes through the wall of the foundation, then additional reinforcement and sealing is also performed here. |

| Thus, if you suddenly notice that the invited craftsmen begin to "sculpt" the rolled material with a continuous canvas from the sole to the base, without making any reinforcement sections, then there is every reason to drive them away. This is a flagrant violation of the established technology, and the reliability of waterproofing will not be ensured. Despite the elasticity of the material, with this approach it is almost impossible to completely eliminate the creation of air sinuses. And in the listed complex areas, where the waterproofing will definitely experience the greatest stresses, the material can simply break through over time. |

| So, they start with reinforcement, and, in particular, with the transition from concrete preparation to the base of the foundation. |

| A fragment is cut out in such a way that its length does not exceed 1000 mm, and at least 100 mm of the deposited material is found on each of the planes of the section to be reinforced. The overlap of adjacent amplification strips of the same level is not less than 100 mm. By the way, this rule is observed in all amplification sections. |

| The cut fragment is rolled up and applied to the intended area. Fusion begins with a transition fillet. |

| Then the upper section is fused onto the vertical wall. |

| After that - the bottom one, for which it is gently pushed on and lifted with a hook. |

| The glued fragment must be rolled over its entire area with a manual silicone roller to ensure its snug fit to the surface, without air pockets. |

| A kind of "indicator" of the quality of the sticker will be a roll of molten bitumen protruding along the entire perimeter. |

| The next section of reinforcement is the transition from the vertical wall of the sole to its horizontal part. |

| The rules are the same here, the fusing technology also has no special features. |

| The next reinforcement belt is in the transition strip from the sole to the foundation wall, through the transition fillet. |

| The operating procedure and rules are exactly the same as on the reinforcement belt when switching from concrete preparation to the sole. |

| All horizontal reinforcement belts are not brought to the outer or inner corners by about one standard stripe, since they must lie on top of the corner reinforcement. Move to the outer vertical corners. They are enhanced with several fragments. To begin with, cut out the "heel", which is notched at the top and bottom, as shown in the illustration. |

| After fusing and smoothing, it will look something like this. |

| Next, a strip is cut out, which will completely cover the vertical joint of two planes. A 100 mm allowance is made at the top and bottom, which is notched in the center. |

| First, a vertical section is welded on both sides of the corner. |

| Then the lower "petals" are glued, which will disperse to the sides ... |

| ... and then the upper ones - they, on the contrary, will lie overlapping one on top of the other. |

| As a result, after fusion, this gain section will look something like this. |

| A similar operation is carried out on the outer corner at the transition from the sole to the vertical wall of the foundation. The only difference can be that the upper edge sometimes does not start on the horizontal surface of the tape, but breaks off at the planned height. |

| After the missing bands of horizontal gain levels lie here, the outer corner will take on a finished form. |

| Now the problem of the inner corners. To begin with, a heel fragment is cut out, which will be fused in the fillet area with a transition to a horizontal surface. |

| The same fragment after fusion into place. |

| Then a fragment is cut out that will overlap the vertical part of the corner. At the bottom, a corner-"nose" is cut out on it, which is cut in two, and the top should be about 100 mm higher than the level of the transition to the horizontal surface. |

| First, this fragment is fused and rolled on a vertical surface, alternately on both planes, converging in a corner. |

| Then the lower part is carefully glued, with the overlapping of the cut corners. |

| After that, the protruding edge along the corner line is cut in two. The resulting "wings" are fused onto a horizontal surface. |

| The gap remaining between them is covered with a patch - "heel". |

| After fusion, the top of the reinforced inner corner will look like this ... |

| ... and the bottom end of the node is like this. In a similar way, the inner corner is reinforced in the area of transition from the base to the foundation wall. Again, the difference is that the waterproofing layer may not reach the very top of the foundation tape. |

| Proceeding to fusion of the main areas of waterproofing. In this case, they start from the bottom, so that the first fragment begins on the concrete preparation and ends on the horizontal plane of the sole, along the line of the transition fillet. |

| Fusion starts from the bottom line of the foundation slab and goes up. |

| After that, the remaining lower section on the concrete preparation is lifted with a hook - and welded on. As a result, you should get such a "picture". Work continues in the same order along the entire perimeter of the foundation, providing an edge overlap of the canvases of 100 mm. In this case, it is necessary to ensure that the gap between the seams of the reinforcement and waterproofing belts is at least 300 mm. |

| For joining at the outer corners, the sheets are trimmed along the corner line, and from below - diagonally. |

| Outside corner after fusion of the first waterproofing layer. |

| The inner corner is also cut diagonally from the bottom. |

| Internal corner after joining two waterproofing sheets. |

| The remaining gap between the canvases is closed with a weld-on patch, which is kept in the recommended dimensions. |

| After the installation of the lower belt of vertical waterproofing is completed, they proceed to fusing the material on the main surface of the foundation walls. Fragments are cut to the desired length, but taking into account the rule - when manually feeding a roll, its length should not exceed two meters. With mechanized feeding - you can use whole rolls. |

| The lower edge of the canvas should overlap the edge of the mounted lower tier by 150 mm, and the offset of the vertical seams should be at least 300 mm. |

| First, the roll is welded up from the fillet ... |

| ... and then the rest of the lower part is welded. |

| If there is a need to use several fragments in one vertical row, then the end overlap should be at least 150 mm. |

| When fusing an adjacent vertical row, the rule is taken into account that the gap of end overlaps on a vertical surface cannot be less than 500 mm. |

| Work is carried out in the same way until the walls of the foundation are completely covered to the top, with a possible approach to the horizontal plane of the tape and its overlap, or to a predetermined level. In this case, it is taken into account that the upper edge of the waterproofing on the plinth cannot be lower than 300 ÷ 500 mm from the ground surface. |

| If necessary, perform the second and even the third continuous layer of waterproofing, again, starting from the surface of the concrete preparation. In this case, they are guided by the already listed rules and a similar scheme - each subsequent layer overlaps the previous one with its edge. In addition, before fusing each next layer, the external and internal corners are reinforced again - according to the principle shown above. |

| In the event that the mounted waterproofing ends on the surface of the basement, its edge must be additionally secured and sealed. For this, the edge is pressed against the base / plinth surface with a special profile rail using dowels. |

| A deformation gap of the order of 5 ÷ 10 mm is necessarily left between adjacent rivers. |

| The same clearance must be maintained at all angles. The installation step of the dowels is 100 mm between the first and the second from the corner or edge of the rail, and then 200 mm. In this case, the extreme dowel should be located no closer than 30 ÷ 50 mm from the corner. |

| The top of the profile pressure strip has an outwardly bent edge. This gap is tightly filled with a special polyurethane sealant "TechnoNIKOL No. 70". |

| The sealant is applied in a continuous strip, including in the areas where the pressure strip breaks. At this, the vertical waterproofing of the foundation with roll materials can be considered, in principle, complete. |

| But the waterproofing layer still needs protection from mechanical damage when backfilling the soil. If the foundation is not supposed to be insulated, then effective protection can be performed using a special profiled membrane of the "PLANTER standard" type. By the way, it will become another additional barrier against moisture penetration. |

| The membrane is covered with the surface of the outer walls of the foundation, placing it with spikes against the wall and fixing it from above using dowels with wide caps. Important - any mechanical fasteners with drilling holes in the wall are allowed only above the ground level, since it is strictly forbidden to violate the waterproofing below. |

| Additionally, it is convenient to fix the membrane in height with special fasteners, which have a foot with a self-adhesive base and are perfectly adhered to the waterproofing surface. |

| These retainers then simply pierce the membrane, holding it in position. |

| Rules for installing and joining membrane sheets: - Its upper edge should be about 300 mm higher than the build-up waterproofing. |

| - Overlap of adjacent canvases - at least four thorns. |

| - Both the outer and inner corners must be covered with continuous strips, so that each side has a minimum width of 1000 mm. |

| - The joints of the membranes, in order to avoid the ingress of soil into them during backfilling, are glued with strips of sealant tape. Gluing is carried out from top to bottom, gradually removing the substrate covering the adhesive layer. |

| - And, finally, it is advisable to fix the upper edge of the profile membrane with a special clamping profile. The rules for its installation are similar to those discussed above for the profile that fixes the waterproofing. |

| After that, you can safely proceed to backfilling, carrying out a thorough layer-by-layer compaction of the soil. |

In the same case, if the foundation requires insulation (and this event is always highly recommended!), The role of protecting the waterproofing from mechanical damage will be assumed by a layer of extruded polystyrene foam. But this is already a topic for separate consideration.

Insulation of the foundation is a guarantee of both its durability and comfort in the house!

It would seem an unnecessary task - after all, the foundation does not directly contact the living quarters. However, the importance of quality is extremely high! More about this - in a special publication of our portal.

At the end of the publication - a video about waterproofing the foundation with roll materials, which can also be of help in completing this stage of building a house on your own.

Video: waterproofing the foundation with roll materials "Technonikol" - video instruction

A distinctive feature of the tape-type foundation lies in its very name. It is a closed chain - "tape" (reinforced concrete strip, laid under the load-bearing walls). Due to the use of strip foundations, the resistance to soil heaving forces is increased, while the risk of skewing or subsidence of the building is minimized.

Strip foundation - photo of a freshly poured structure

It is such a foundation that is built on dry or heaving soils... Moreover, the greater the weight of the future structure, the deeper the foundation is laid (sometimes even up to 3 m, depending on the depth of soil freezing and the level of underground waters).

These and other characteristics are regulated by GOST 13580-85 and SNiP 2.02.01.83.

GOST 13580-85. REINFORCED CONCRETE PLATES OF TAPE FOUNDATIONS. Technical conditions. Download file

SNiP 2.02.01-83. FOUNDATIONS OF BUILDINGS AND STRUCTURES. Download file

During construction, special attention is paid to waterproofing, since the strength, quality and durability of the structure will depend on it. In the absence of protection, groundwater and precipitation can significantly harm concrete, and the consequences can be the most dire - from permanent dampness to subsidence and cracking of walls. For this reason, do-it-yourself waterproofing of the strip foundation is one of the most critical stages.

Waterproofed foundation - photo

Below is the average depth of soil freezing in different regions... If your region is not in the table, then you need to focus on the one that is closer than others.

Regardless of the chosen method of isolation (we will talk about them a little later), a number of technical requirements must be adhered to in the work.

- It is imperative to take into account the level of groundwater, because the type of insulation depends on it.

- It is also necessary to take into account the conditions for the future operation of the facility (if, for example, a warehouse is being built, then the requirements for waterproofing will be more stringent).

- It is also necessary to remember about the possibility of flooding during large floods or atmospheric precipitation (in particular, this applies to loose soil).

- The force of "swelling" of the soil during frosts also plays an important role (during defrosting / freezing, the structure and volume of water change, which can lead not only to the rise of the soil, but also to the destruction of the foundation).

The main methods of waterproofing

Waterproofing can be of two types - vertical and horizontal. Let's consider each of the options.

Important information! When constructing the base, you do not need to save money and give up the sand "cushion". Sand is needed not only to prevent concrete leakage, but also to prevent flushing of the structure.

It is performed even during the construction of the foundation, while additional time (15-17 days) may be required for preparatory measures. The main function of such insulation is to protect the base in the horizontal plane (mainly from capillary groundwater). An important component horizontal waterproofing is a drainage system that is equipped with a high level of groundwater.

It is worth noting that under the "tape" there must be a sufficiently strong base, on top of which the waterproofing layer will be laid. Often for this, a "pillow" is cast with a slightly wider width than that of the future foundation. In the absence of the need for high quality (for example, if the foundation is being built for a bath), it is enough to prepare a screed of sand and cement in a 2: 1 ratio. During the Soviet era, asphalt screed was made, but today this technology is practically not used.

The horizontal waterproofing procedure consists of several stages.

Stage 1. The bottom of the pit, dug out under the base, is covered with a sandy "pillow" about 20-30 cm thick (instead of sand, you can use clay) and carefully compacted.

Stage 3. When the screed is dry (it takes about 12-14 days), it is covered with bitumen mastic and a layer of roofing material is attached. Then the procedure is repeated: applying mastic - fastening roofing material. On top of the second layer, another screed of the same thickness is poured.

Stage 4. When the concrete hardens, the construction of the foundation itself begins, the surfaces of which are additionally covered with vertical types of waterproofing (they will be discussed later).

Important information! If the building will be constructed from a log house, then the top of the foundation must also be waterproofed, since the first crown will be installed there. Otherwise, the wood may rot.

Drainage

Drainage may be required in two cases:

- if the permeability of the soil is low and water accumulates, and is not absorbed by it;

- if the depth of the foundation is lower or corresponds to the depth of the groundwater.

The algorithm of actions for arranging the drainage system should be as follows.

Stage 1. Around the perimeter of the structure - about 80-100 cm from the foundation - a small pit 25-30 cm wide is digging.The depth should exceed the depth of the foundation by 20-25 cm.It is important that the pit has a slight slope in the direction of the catchment, where water will accumulate.

Stage 2. The bottom is covered with geotextiles, while the edges of the material must be wrapped on the walls by at least 60 cm. After that, a 5-cm layer of gravel is filled up.

Stage 3. A special drainage pipe is installed on top, observing a slope towards the water collector of 0.5 cm / 1 linear. m.

Pipe laying on geotextiles and crushed stone backfilling

Thanks to this design, water will flow into the drainage pipe, while it (pipe) will not become clogged. Moisture will be discharged into a drainage tank (it can be a well or a pit, and the dimensions depend on the flow of water and are determined on an individual basis).

Drainage well prices

drainage well

Vertical waterproofing

Insulation vertical type- This is the processing of the walls of the finished foundation. There are several ways to protect the base, which are possible both during the construction of the building and after construction.

Table. Strengths and weaknesses of the most popular waterproofing options

| Material | Operational period | Ease of repair | Elasticity | Strength | Cost per m² |

|---|---|---|---|---|---|

| 5 to 10 years old | ★★★☆☆ | ★★★★★ | ★★☆☆☆ | About 680 rubles | |

| Polyurethane mastic | 50 to 100 years old | ★★★☆☆ | ★★★★★ | ★★☆☆☆ | About 745 rubles |

| Rolled bituminous materials | 20 to 50 years old | ★☆☆☆☆ | - | ★☆☆☆☆ | About 670 rubles |

| Polymer membranes (PVC, TPO, etc.) | 50 to 100 years old | - | ★☆☆☆☆ | ★★★☆☆ | About 1300 rubles |

Inexpensive and simple, and therefore the most popular way to waterproof the foundation. It implies a complete treatment with bituminous mastic, which penetrates into all cracks and voids and prevents moisture from entering the house.

Important information! When choosing one or another bitumen mastic, pay attention to the marking - this will help you find out the heat resistance of the material. For example, mastic labeled MBK-G-65 has a heat resistance (for five hours) of 65 ° C, and MBK-G-100 - 100 ° C, respectively.

Advantages of bituminous mastic:

- ease of use (you can do it alone);

- affordable cost;

- elasticity.

Disadvantages:

- low speed of work (several layers are required, which takes a lot of time);

- not the best water resistance (even a high-quality application does not guarantee 100% protection);

- fragility (after 10 years you will have to re-process the foundation).

The process of applying the mastic itself is extremely simple and consists of several stages.

Stage 1. Surface preparation. Below are the basic requirements.

- The surface of the foundation must be solid, with beveled or rounded (ø40-50 mm) edges and corners. Fillets are made in the places of transitions from the vertical to the horizontal - so the abutting surfaces will be mated more smoothly.

- For bitumen, sharp protrusions that appear where formwork elements are joined are extremely dangerous. These protrusions are removed.

- Areas of concrete covered with cavities from air bubbles are rubbed with fine-graded cement mortar based on a dry construction mixture. Otherwise, bubbles will appear in the freshly applied mastic, which will burst in 10 minutes after application.

Also, dirt and dust should be removed from the surface, and then dried thoroughly.

Important information! The moisture content of the substrate is a very important indicator and should not exceed 4%. At a higher value, the mastic will swell or begin to flake off.

It is quite simple to test the base for moisture: you need to lay a piece of PE film 1x1 m in size on the concrete surface.And if after a day there is no condensation on the film, then you can safely proceed to further work.

Stage 2. In order to increase adhesion, the prepared base is primed with a bituminous primer.

You can go the other way and prepare a bitumen primer yourself. To do this, bitumen grade BN70 / 30 must be diluted with a rapidly evaporating solvent (for example, gasoline) in a ratio of 1: 3.

One layer of primer is applied over the entire surface, two at the junction. This can be done with a brush or roller. After the primer has dried, the actual mastic is applied.

Stage 3. A block of bitumen is broken into small pieces and melted in a bucket above the fire.

It is recommended to add a small amount of "waste" there during heating. Then liquid bitumen is applied in 3-4 layers. It is important that the material does not cool down in the container, since with another heating it will partially lose its properties.

The total thickness of the waterproofing layer depends on the depth of the foundation (see table).

Table. The ratio of the thickness of the bitumen layer to the depth of the foundation

Stage 4. After drying, the bitumen should be protected as it can be damaged when backfilled with soil containing debris. To do this, you can use rolled geotextiles or EPS insulation.

Prices for bituminous mastic

bituminous mastic

Video - Thermal insulation of the EPPS foundation

Reinforcement

Bituminous insulation needs reinforcement for:

- cold seams;

- junction of surfaces;

- cracks in concrete, etc.

Often, fiberglass and fiberglass are used for reinforcement.

The fiberglass material must be sunk into the first layer of bitumen and rolled with a roller to ensure a tighter adhesion. As soon as the mastic is dry, the next layer is applied. It is important that the fiberglass material is laid with an overlap of 10 cm on both sides.

Reinforcement will provide a more even distribution of the load over the entire insulating strip, minimize the elongation of bitumen in the areas of cracked openings and, as a result, significantly extend the service life.

Fiberglass prices

fiberglass

It can serve as both the main protection and addition to the applied bitumen mastic. Usually roofing material is used for this.

Among the advantages of the method should be highlighted:

- low cost;

- availability;

- good service life (about 50 years).

As for the shortcomings, this can only be attributed to the fact that you cannot cope with the work alone. The algorithm of actions should be as follows.

Stage 1.

Unlike the previous method, there is no need to carefully apply the material, since the mastic is needed exclusively for fixing the roll waterproofing to the base.

Stage 2. With the help of a burner, the roofing material is slightly heated from below, after which it is applied to a layer of hot bitumen. Roofing material sheets are joined with an overlap of 10-15 cm, all joints are processed with a burner.

Stage 3. After fastening the roofing material, you can fill up the foundation, since additional protection is not required here.

Important information! Roofing material can be replaced with more modern materials that are fused onto the base. These can be polymer films or webs with bitumen-polymer spraying (for example, Isoelast, Technoelast, etc.).

Roofing material prices

roofing felt

Video - Waterproofing with roofing material

This method is extremely simple to perform and is used for the purpose of waterproofing and leveling the surface of the foundation. Here advantages of plaster waterproofing:

- simplicity;

- high speed of work;

- affordable cost of materials.

Disadvantages:

- low hydraulic resistance;

- short service life (about 15 years);

- possible cracking.

There is nothing complicated in the application process. First, with the help of dowels, a putty mesh is attached to the foundation, then a plaster mixture with hydro-resistant components is prepared. The mixture is applied to the foundation with a spatula. After the plaster has dried, the soil is poured.

Essentially, it is a dispersion of polymer-modified bitumen particles in water. The composition is sprayed onto the base, providing high-quality waterproofing. Dignity this method is as follows:

- high quality waterproofing;

- no need for special skills;

- durability.

But there is also limitations:

- high cost of the composition;

- low speed of work in the absence of a sprayer.

In addition, liquid rubber is not widely available. For the foundation, a composition of the same type, which is of two types, is quite suitable.

- Elastomix - applied in 1 layer, hardens for about 2 hours. It is not subject to further storage after opening the package.

- Elastopaz is a cheaper option, but it is applied in 2 layers. Tellingly, Elastopaz can be stored even after opening the package.

Stage 1. The surface is cleared of dirt and debris.

Stage 2. The foundation is covered with a special primer. Alternatively, you can use a mixture of liquid rubber and water (ratio - 1: 1).

Stage 3... An hour later, when the primer is dry, a waterproofing material is applied (in one or two layers, depending on the type of composition). It is advisable to use a spray for this, but you can use a roller or brush instead.

Liquid rubber prices

liquid rubber

Video - Treatment of the base with liquid rubber

Penetrating insulation

On the base, previously cleaned of dirt and slightly moistened with water, a special mixture (Penetron, Aquatro, etc.) is applied with a sprayer, which penetrates into the structure by about 150 mm. It is important that the solution is applied in two to three coats.

The main Benefits:

- effective protection;

- the ability to process surfaces inside the building;

- simplicity of work;

- long service life.

Disadvantages:

- insignificant prevalence of such solutions;

- high price.

Making a clay castle

Simple but at the same time effective method protect the base from moisture. First, a pit 0.5-0.6 m deep is dug around the foundation, then the bottom is covered with a 5-centimeter gravel or crushed stone "pillow". After that, clay is poured in several stages (each layer is carefully compacted). The clay itself will act as a moisture buffer.

The only advantage of this method is its ease of implementation.

The clay castle is only suitable for wells and household objects. If we are talking, for example, about a residential building, then this method can be used only as an addition to the already existing waterproofing.

This method of protecting the base appeared relatively recently and consists in the following: mats filled with clay are nailed to the cleaned surface of the foundation using a mounting gun or dowels. The mats should be laid with an overlap, about 12-15 cm. Sometimes, instead of mats, special clay-concrete panels are used, then the joints in this case must be additionally processed.

Overlap - photo

Overlap - photo

In principle, screen insulation is an improved version of a clay castle, therefore it can only be used for utility structures.

Summing up. Which option should you choose?

The best option for waterproofing a strip foundation should include both horizontal and vertical waterproofing. If, for one reason or another, horizontal insulation was not laid during construction, then it is better to resort to bituminous mastic or special plaster. But, we repeat, it will be most effective only in combination with horizontal type protection.

Kirill Sysoev

Callous hands do not know boredom!

Content

Groundwater, moisture, weather dampness - all this poses a natural threat to a building if its base is not reliably protected from water. So that concrete and other materials in the structure of the foundation do not suffer from moisture, creating an atmosphere of dampness in the lower rooms, a number of works must be carried out during construction, the main of which is waterproofing the foundation. What materials, technologies are better suited for this and is it possible to cope with the process on your own - find the answers below.

What is foundation waterproofing

Any waterproofing is a series of works aimed at warming, protecting the foundation from influence, moisture penetration, and reducing the natural absorbency of concrete. This procedure is especially relevant if the house is on wet soil or has a basement, garage, basement. There are different ways than to process the base from moisture:

- bitumen, bituminous mastics are widespread;

- then cement-polymer compositions follow;

- liquid rubber and self-adhesive roll materials are used.

What is it for

Concrete is the main component of any foundation, it has a porous, pliable structure, so liquid from the atmosphere and soil always seeps into it, destroying the integrity of the structure, creating and increasing microcracks. Ultimately, this will help lead to such serious consequences as partial destruction, rotting, crumbling of the house at the base.

Protection from water is necessary for every building in order to increase the period of its safe, guaranteed operation, to protect the house from dampness and its unpleasant components - fungus, mold. Modern waterproofing allows you to eliminate all these dangers with the help of functional, affordable building materials and simple technology.

Horizontal waterproofing

Depending on the characteristics of the material and the terrain, a horizontal or vertical type of procedure is used. The horizontal one provides good protection of ceilings, walls, basements, terraces and balconies from capillary waters, it fits along the edge of the base, just above the blind area. For implementation, a roll or impregnation method is used. Horizontal waterproofing of the foundation is carried out at the beginning of construction, before the construction of the walls.

Vertical waterproofing

It is better to use light bituminous mixtures for this, which insulate the building and do not weigh down its structure. Vertical waterproofing is necessary to protect the side walls, frame, doorway assemblies, underground rooms, from the penetration of surface water. Since this part of the building is often exposed to external factors, an additional layer must be applied on top of the main protective one.

Roll

Gluing waterproofing of the foundation is made with the help of materials such as roofing material, glass insulation, glassine, which are glued in several layers using mastic or special glue. Other methods are film diffusion membranes, which have high vapor permeability and protect the interior of the building well, or bitumen, polymer rolls, hot-bonded, floating (for better connection to the surface).

You should calculate the amount in advance necessary material for horizontal protection from groundwater: the future protective layer should be about 3 mm, if the base sole is at least 3 meters. The thickness and quantity of coatings depend on the quality and strength of the material; the recommended standards are often indicated on the packaging.

Coating

Bituminous insulation is used when soil moisture is low, when the groundwater is at least 2 meters below the basement level. It protects well against capillary moisture, it is applied in 3-4 layers by hand or using a mechanical spray. Material - bitumen, bitumen-polymer mixtures and rubber mastics, additional coatings with a base, varnish, paint. Commercially available are cold, soft, ready-to-use, or hot, hard, which must be preheated.

How to make waterproofing

Craftsmen recommend laying horizontal waterproofing layers before erecting the main supporting structure: clay is poured onto the bottom of the pit, covered with a concrete screed, then two layers of bitumen and roofing material and one more screed. If the soil has a tendency to store water, it may be necessary to build a drainage system for better protection. Foundation waterproofing takes place in several stages:

- preparation of a trench with a width of at least 1 meter, in depth - 0.5 meters below the foot of the base;

- grouting the outer layer for better adhesion to moisture-proof coatings;

- primer using the selected technology.

Waterproofing strip foundation