Highly sugared corn syrup is most often used to prepare table syrups. You can also use maltose molasses for this purpose, but its use in syrups requires additional purification and clarification with activated carbon. Thus, corn syrups quite common.

The difference in the recipe will only be a slight reduction in the percentage of granulated sugar, since maltose molasses is sweeter than molasses obtained as a result of acid hydrolysis.

Also developed syrup technology based on a mixture of both types of molasses - maltose and acidic.

The pleasant taste and high content of easily digestible sugars (glucose and maltose) make syrups very valuable dietary products, suitable for baby food, for use in cooking and in the canning industry.

Table syrups can be used instead of honey and jam, as a gravy for milk porridges; They can also be used for compotes, various flour and confectionery products.

Sweet syrups

Recently, measures have been taken to further increase the nutritional value of syrups. We are talking about new recipes for molasses table syrups developed by the Belarusian Research Institute of Food Products Industry. These recipes use natural essences instead of aromatic essences. fruit juices.

The Institute has developed three syrup recipes: cherry, strawberry and cranberry. On average, these syrups contain about 75%, approximately 10% sugar, 15% natural juices and 0.3% citric acid. Citric acid is not added to cranberry syrup, since cranberry juice itself contains a sufficient amount of acid.

It goes without saying that syrups based on new recipes have a higher nutritional value, since, in addition to sugars, they also contain vitamin C (especially if freshly squeezed juice is used), natural aromatic substances, enzymes and other biologically valuable substances.

Syrups of a different composition, also using , are produced by the Moscow Soft Drinks Plant.

Here, for example, is a syrup with the curious name “Carotella”. This seemingly exotic name comes from the word “carotene”. Carotene, or provitamin A, is a yellow pigment that creates the characteristic color of carrots and apricots. “Carotella” contains natural carrot juice and corn syrup.

Another similar syrup, Abricotin, is also prepared from corn syrup and dried apricot extract and acidified with citric acid.

Syrup (French sirop) is a concentrated sugar solution or a mixture of individual sugars (sucrose, glucose, fructose, maltose) in water or natural fruit juice. The sugar content of syrup usually ranges from 40 to 80%. To prepare sugar syrup, sugar is dissolved in water and boiled to a certain density. The readiness of the syrup is determined by organoleptic characteristics, boiling point - by a thermometer, density - by a hydrometer or refractometer. Sugar and water (1:1.1) are loaded into the digester and, stirring continuously, bring to a boil (temperature 101–102 °C). Then the hot syrup is cooled to a temperature of 40–50°C, filtered and flavored with light wine, cognac or the “Confectionery” wine-alcohol composition (dark or red wines give the biscuit a gray-dirty hue). Fruit biscuit products are flavored with fruit juices and fruit-flavored wines; coffee cakes - with special coffee syrup; biscuit cream products - syrups, flavored proteins, light wines, cognacs, light liqueurs. It is not recommended to use honey and mint essences for flavoring, as the cream will taste unpleasant. Invert syrup has a yellowish transparent color. Density at a temperature of 20°C 1290–1330 kg/m3. The content of invert sugar in the syrup must be at least 50%, which is 70–80% of the total amount of sugar in the syrup. The technological process for producing invert syrup consists of the following operations: heating an aqueous solution of sugar with acid, cooling to 80–90°C and neutralization. First, heat the sugar solution (for 100 parts of sugar, take 44 parts of water) and, stirring, bring to a boil. Then add acid and cook for 25–30 minutes (temperature 107–108 °C). When a solution is boiled with the addition of acid, an inversion process occurs, which consists in the splitting of sucrose into fructose and glucose. The acid is a neutralizer and does not participate in the hydrolysis (inversion) process.

After boiling, the syrup is cooled to 80–90 °C and tasted. Soda is added to the syrup in the form of a 10% solution. In this case, rapid foaming and sedimentation are observed. After settling, the syrup is filtered and stored at a temperature of 16-20°C for a month or more. Invert syrup is used as a substitute for molasses, as it has anti-crystallization properties; They are also used in the production of cookies and gingerbread as an independent component that improves their quality and gives the products a golden-brown color.

The readiness of sugar syrup is determined by characteristic external signs, which confectioners call “samples”. There are twelve “tests” in total. Here's what these samples mean:

1 Liquid syrup. This syrup has no stickiness, its thickness and sugar content is almost unnoticeable. It is used for pouring winter compotes and dried fruit compotes, sometimes for light sorbets (a mixture of hot syrup and fruit juice).

2. Thin thread. A sticky syrup that, when squeezing and unclenching one drop with your fingers, produces a thin, quickly breaking, fragile thread. It is used for jam from dense, hard fruits - pears, quinces, dense apples, carrots, and sometimes for pouring winter compotes from soft berries (strawberries, raspberries), for making jelly.

3. Middle thread. The thread is thin, but holds a little stronger. Syrup of this strength is used for jam.

4. Thick thread. A thick syrup in which the fingers are separated with force, forming a strong and rather thick thread that can harden. Used for all jams made from tender berries and for canning most berries and fruits.

5. Weak fondant. If you put a small amount of such melted sugar in a glass of cold water, a loose mass is formed, reminiscent of thick sour cream in consistency. This test is a sign that you need to be prepared for the sugar to thicken until the next test. It has no independent meaning.

6. Fudge. If you drop such melted sugar into a glass of cold water, the “drop” solidifies into a piece similar in consistency to thick butter. This sample is very unstable and can quickly go into the next one, therefore, if this is what the recipe calls for, then you must immediately stop the boiling of the sugar. Used to make fudge and candy fillings.

7. Weak ball (semi-hard ball). Sugar in cold water hardens to the consistency of bread crumb. You can mold it into a soft, pliable ball. Used for fondants, toffees, candy fillings, candied fruit jams, figs, and sometimes for gingerbread (when mixed with honey and flour).

8. Hard ball (or strong ball). Boiling sugar in a glass of cold water hardens into a dense, hard ball, which after a while loses its ability to wrinkle. This sample is used exclusively for sweets, toffees, and toffees.

9. Crack. Testing the sample is done like this: take boiling sugar on a fork and blow on it with all your might. If the sugar instantly turns into a film or bubble and flies off the fork entirely, then the “crack” sample is ready. Used for meringue cookies, cakes, decorations and candies.

10. Caramel. Boiling sugar poured into cold water should form a piece, an icicle, that does not stick to the teeth and crumbles into crystals like glass when pressed or hit. Sugar of this type is used for caramels - sweets, lollipops, montpensiers.

11. Bypass. The fragility of sugar is the same as in sample No. 10, but the color of the sugar is already yellowish-brown. Very often, this particular test - bypass - is mistaken for caramel, since in many confectionery books and manuals the term “sugar is caramelized” is used, which means yellowing and even slight burning of sugar, its browning and the appearance of a characteristic “caramelized” smell as a result of the bypass (bypass) actual caramel sample. The transfer is used for some lollipops, caramel candies, and especially for roasting, as well as for tinting many confectionery products, drinks (including beer) and creams or giving them a special, “caramelized” aroma (for example, punch, burnt liquor).

12. Combustion. Zhenka. The sugar turns brown, and an acrid smoke and burnt smell appears. This sugar is diluted with boiling water to form a sticky syrup and is used for tinting sweets, candy fillings, gingerbreads, icing, kvass, creme brulee ice cream, pastries, cakes, various drinks and even some soups - beer, bread, egg, berry or sweet milk.

Send your good work in the knowledge base is simple. Use the form below

Students, graduate students, young scientists who use the knowledge base in their studies and work will be very grateful to you.

Posted on http:// www. allbest. ru/

- Introduction

- Section 1. Characteristics of the final production product

- 1.1 Characteristics of licorice root syrup

- 1.2 Composition of soloccus root syrup

- 1.3 Pharmacological action of licorice root syrup

- 1.4 Appearance of licorice root syrup

- 1.5 Packaging of licorice root syrup

- 1.6 Labeling of licorice root syrup

- 1.7 Transporting licorice root syrup

- 1.8 Storing licorice root syrup

- Section 2. Chemical production scheme

- Section 3. Production flow diagram

- Section 4. Hardware production diagram

- Section 5. Characteristics of feedstock, materials and intermediate products

- Section 6. Description of the technological process

- Section 7. Material balance

- Section 8. Recycling and disposal of production waste

- Section 9. Production control and production standardization

- Section 10. Safety precautions

- Section 11. Environmental protection

- Section 12. List of production instructions

- Bibliography

Introduction

licorice raw materials syrup production

Syrups are concentrated aqueous solutions of sucrose, which may contain medicinal substances, fruit food - extracts.

Syrups are thick, clear liquids that have a characteristic taste and smell, depending on their composition.

At the moment, there is a big problem in medicine and pharmacy - a small range of dosage forms for children over 3 years old and a complete absence of dosage forms for children under 3 years old. This is explained by the fact that for manufacturing companies, clinical trials of drugs on children are very expensive and lengthy. They found a way out of this problem by producing drops, powders, and mixtures, but soon the number of pharmacies producing these dosage forms for young patients decreased.

Currently, licorice root syrup is used in adults and children as an expectorant for diseases of the upper respiratory tract accompanied by cough, mainly in the presence of poorly separated, thick and viscous secretions (especially in children, pregnant women and the elderly). .

The purpose of the work was to study scientific documentation, educational and reference literature to draw up a technological and instrumental scheme for the production of licorice root syrup, to outline the technological process of its production, step-by-step control, safety precautions, and environmental protection of this production.

In connection with this, the following tasks were drawn up:

Describe the technological process for producing licorice root syrup;

Calculate loads of medicinal and auxiliary substances;

Outline the theoretical basis for the production of licorice root syrup.

Chapter1. Characteristics of the final production product

1.1 Characteristicsyruplicorice root

Licorice root syrup (Sirupus glycyrrhizae)

1.2 Compoundsyruplicorice root

Thick licorice root extract 4 g

Sugar syrup 86 g

Ethyl alcohol 90% 10 g

1.3 Pharmacologicalactionsyruplicorice root

Pharmacological action: expectorant. Used in complex therapy of acute respiratory diseases. Indications for use are: acute and chronic bronchitis, tracheitis, atelectasis due to blockage of the bronchi with mucus plugs, bronchiectasis, pneumonia, bronchial asthma, rehabilitation of the bronchial tree in the pre- and postoperative period.

1.4 Externalviewsyruplicorice root

A thick liquid of yellow-brown color, with a sweet taste and characteristic odor. During storage, sediment may form.

1.5 Packagesyruplicorice root

60, 100 and 125 g of the drug in orange glass bottles with a screw neck, sealed with PE stoppers and screw caps. Each bottle is placed in a cardboard pack. It is allowed to pack bottles without a pack in a group package.

1.6 Markingsyruplicorice root

The label indicates the manufacturer, its trademark, postal address, telephone number, name of the drug in Russian, quantity of the drug in grams, composition, storage conditions, batch number, registration number, date of manufacture, shelf life, barcode. The number of bottles and handling warning labels are indicated on the group container. Containers are marked in accordance with GOST 14/92-96.

1.7 Transportationsyruplicorice root

Transportation according to GOST 17768-90. Medicines are transported in closed vehicles and containers in accordance with GOST 20435 with all types of transport according to group 5 OZh4 GOST 15150 and additional requirements specified in the regulatory and technical documentation for specific types of medicines, and the rules for the transportation of goods in force for the corresponding mode of transport.

1.8 Storing licorice root syrup

In a dry place at a temperature of 5 to 25 °C. Keep out of the reach of children and away from light. Shelf life: 2 years. Do not use after expiration date. .

Chapter2. Chemical production scheme

There are no chemical transformations during the production of licorice syrup, so this section is missing.

Chapter3. Production flow diagram

Guided by the basic rules for preparing licorice root syrup, I propose a rational technological scheme for the production of sugar syrup, which includes the following stages:

BP-1 Pre-production:

BP 1.1. Preparation of disinfectant solutions

BP 1.2. Preparation of equipment and premises

BP 1.3. Personnel training

VR 1.4. Ventilation air preparation

BP 1.5. Preparing containers and bottles

BP 1.6. Obtaining purified water

BP 2.1. Weighing out medicinal and auxiliary substances

BP 2.2 Weighing sugar

BP 2.3. Measuring purified water.

TP-3 Preparation of licorice root syrup

TP 3.1. Heating purified water

TP 3.2. Adding sugar

TP 3.3. Removing foam, boiling syrup

TP 3.4. Filtration of sugar syrup

TP 3.5. Mixing sugar syrup with thick licorice extract

TP 3.6. Filtration and cooling

Standardization

UMO 4.1. Packing

UMO 4.2. Packaging in bottles

UMO 4.3. Marking

Production flow diagramPertussin syrup

Fig.1. Technological scheme for the production of Pertussin syrup

Chapter4. Hardware production diagram

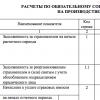

Table 1. Equipment

|

Name |

Quantity |

Note |

||

|

Container for preparing disinfectant solution |

||||

|

Bath for washing containers |

||||

|

Drying cabinet |

||||

|

Water distiller for obtaining purified water |

||||

|

Collection of purified water |

||||

|

Measuring device for purified water |

||||

|

Technical floor scales |

||||

|

Steam jacket boiler, reactor |

||||

|

Nutsch filter |

||||

|

LF packaging machine |

||||

|

Technical control department |

Rice. Hardware diagram for the production of licorice root syrup

Chapter5. Characteristics of raw materials, materials, products

Table 2. Characteristics of raw materials.

|

Name |

Designation |

Variety or article |

Indicators required for verification |

Note |

|

|

A. Main raw materials |

|||||

|

1. Licorice root extract is thick |

Brown liquid with special smell |

For cooking |

|||

|

2. Purified water |

In accordance with FS 42-0324-09 |

Colorless transparent liquid, odorless and tasteless. |

For cooking |

||

|

4. Sucrose |

Colorless monoclinic crystals. When molten sucrose hardens, an amorphous transparent mass is formed - caramel. Sucrose has a high solubility. Soluble in water and ethanol. Malorast. in methanol. |

For cooking |

|||

|

5. Ethyl alcohol 96% |

GF X (Article 632) |

A transparent, colorless, mobile, volatile liquid with a characteristic alcoholic odor and pungent taste. Boils at 78°. It is highly flammable and burns with a bluish, faintly glowing, smokeless flame. Miscible in all proportions with water, ether, chloroform, acetone and glycerin. |

|||

|

B. Help- body materials |

|||||

|

1. Bottles |

For packaging |

||||

|

2. Paper etiquette. |

For packaging |

||||

|

3. Wrapping paper |

For packaging |

||||

|

4. Writing paper |

For packaging |

||||

|

5. Drinking water |

|||||

|

6. Purified water |

|||||

|

7. Cardboard box |

For packaging |

||||

|

8. Stamp paint |

For packaging |

||||

|

9. Polyethylene plugs |

For packaging |

||||

List of intermediate products obtained in production and requirements for their quality.

Table 3. Quality requirements

Chapter6. Description of the technological process

BP-1 Pre-production:

VR-1.1. Preparation of disinfectant solution As a disinfectant. solutions use: 3% hydrogen peroxide solution with 0.5% detergent (1); chloramine B solution - 1% (2); degmin solution 1%.

VR-1.2. Preparation of equipment and premises

The equipment is washed and disinfected with a 3% hydrogen peroxide solution, followed by rinsing with water. Check the serviceability of the equipment. Wet cleaning of production premises is carried out daily. Panels, walls, doors, windows, ventilation air ducts are wiped with a cloth moistened with a 3% solution of hydrogen peroxide with the addition of 0.5% detergent at least once a week. To disinfect floors, use a solution of chloramine B. General cleaning is carried out once a month.

VR-1.3. Personnel training

All persons involved in the production of medicines must undergo a medical examination and bacteriological examination. Before starting work, personnel must put on overalls, safety shoes, and wash their hands with soap and a 1% degmin solution.

VR-1.4. Ventilation air preparation

Indoor air purification is two-stage. In winter, the air is additionally heated. The filter chambers are washed with disinfectant. solution.

VR-1.5. Preparing containers and cans

The containers are washed and disinfected (3% hydrogen peroxide solution) followed by rinsing with water.

The jars are washed in a bath, dried and sterilized in a cabinet at 180°C -60 minutes.

Polyethylene lids are washed in a bath, disinfected in a 6% hydrogen peroxide solution, washed with purified water and dried in a cabinet at 40 °C.

VR-1.6. Obtaining purified water

Purified water is obtained from a distiller.

BP-2 Preparation of medicinal and excipients

BP 2.1. Weighing out medicinal and auxiliary substances

On floor technical scales, thick licorice root extract 4 g, ethyl alcohol (96%) 10 g are measured.

BP 2.2. Weighing out sugar

Sugar is weighed on ordinary technical scales.

BP 2.5. Measuring purified water

Purified water is obtained by distillation in an aqua-distiller.

TP-3 Preparation of licorice root syrup.

TP 3.1. Heating purified water

Purified water is poured into a steam-heated syrup boiler, steam is released into the steam jacket, and the water is heated to a temperature of 60-70 C°.

TP 3.2. Adding sugar

With continuous stirring, pour in refined sugar.

After the sugar is completely dissolved, the syrup is allowed to boil 2 times.

TP 3.3. Removing foam, boiling syrup

The resulting foam is removed with a slotted spoon.

The cessation of foam formation on the surface of the syrup indicates its readiness.

TP 3.4. Filtration of sugar syrup

The finished syrup, while hot, is drained through the boiler drain valve and filtered through a filter unit. A sample is taken for analysis and, if the result is satisfactory, the finished syrup is mixed with potassium bromide powder and liquid thyme extract, as well as with all other auxiliary substances.

TP 3.5. Mixing sugar syrup with thick licorice extract

Sugar syrup is loaded into a cast-iron enameled tank and a thick extract of licorice root is added while stirring. Mix with alcohol.

TP 3.6. Filtration and cooling

The finished syrup is filtered through a filter unit and cooled. A sample is taken for analysis.

Standardization of syrups is carried out in accordance with OST 91500.05.001-00.

UMO-4 Packaging, packaging and labeling

UMO 4.1. Packing

The syrup is packaged into bottles using a dispenser.

UMO 4.2. Packaging in bottles

The weight of the packaging is controlled. The bottles are packed in cardboard boxes, which are sealed with a strip of paper.

UMO 4.3. Marking

A label is placed on the boxes indicating the name of the product and the number of bottles in the box, as well as the manufacturer’s trademark. The box is marked with manipulation signs. Some of the finished products are sent to QA control.

Dispensing is carried out in pharmacies without a doctor's prescription.

Chapter7. Material balance

Table 4. Working recipe taking into account the consumption coefficient

Licorice root syrup composition:

Thick licorice root extract 4.0 g

Sugar syrup 64% 86.0 g

Ethyl alcohol (96%) 10.0 g

Raw material

1) 4kg - 100kg

x=12 kg*1.07=12.84 (thick licorice extract)

2) 86 kg - 100 kg

x= 258*1.07=276.06 (sugar syrup)

x = 176.68(sucrose)

3) 276.06 -176.68=99.38l (water)

4) 10kg-100kg

x=30kg*1.07=32.1 (ethyl alcohol)

Technological output:

z= 300/321*100%=93.46%

Technological waste:

E= 21/321*100%=6.54%

Expense ratio:

Color = G1/ G2

Crash = 321/300 = 1.07

Composition of licorice root syrup per 300 kg:

thick licorice root extract 12.84 kg

sucrose 176.68 kg

purified water 99.38 l

ethyl alcohol (96%) 32.1 kg

Chapter8. Recycling and waste disposal

There is no recycled or neutralized waste in the production of licorice root syrup.

Chapter9. Production control and production standardization

The following controlled parameters are checked: cleanliness of the bottles - visually; heating temperature; preparing syrup - thermometer; foaming - visual.

Full analysis of the finished product - density of sugar syrup - 1.301 -1.313 g/cm; refractive index - 1.451-1.454; purity - the implementation of molasses, invert sugar, heavy metals and the absence of chlorides, sulfates; color and pH (GF X, XI).

Chapter10. Safety precautions, fire safety and industrial sanitation

Sugar syrup is prepared in compliance with safety and fire safety instructions.

Chapter11. Environmental protection

In order to ensure the water resources of the air basin, measures are taken to prevent liquid and solid emissions from entering the environment.

Chapter12. List of production instructions

1) Technological instructions (industrial regulations).

2) Safety and fire safety instructions.

3) Equipment operating instructions.

Bibliography

1. State Pharmacopoeia of the USSR X ed. - 1968, art. 573

2. State Pharmacopoeia of the Russian Federation: 12th edition. Part 1. - M.: “Scientific Center for Expertise of Medicinal Products”, 2008. - 704 p.

3. OST 64-02-001-2002 Control laboratories of quality control departments of pharmaceutical manufacturers // Requirements and accreditation procedure for technical competence // OST 64-02-001-2002. M.:, Medicine. - 2003 - P.7.

4. GOST 22840-77 Licorice root extract // Technical conditions

5. GOST R 52249-2009 - Rules for the production and quality control of medicines.

6. State register of medicines //MedAboutMe.ru//

7. Arzamastsev A.P., Dorofeev V.L. Medicines: modern requirements for standardization and quality control // New Pharmacy. - 2007. - No. 5. -S. 58-61.

8. Azhgikhin I.S., Drug technology: Textbook for pharmaceutical schools. - M:. - 1980.- P. 440.

9. Bobylev R.V., Gryadunova G.P., Ivanova L.A. and others. Technology of dosage forms. - M.: “Medicine”. - 1991. - vol. 2, pp. 491-503.

10. Gavrilov A.S., Pharmaceutical technology. Manufacturing of medicines. - M., GEOTAR-Media. - 2010. - P.624.

11. Ivanov L.A., Kondratiev T.S., Zelikson Yu.I.. Technology of dosage forms. - volume I.- M:. - 1991. - P.496.

12. Ivanova L.A., Bobyleva R.V., Gryadunova G.P., Technology of medicinal

Form: Textbook for universities, Volume II.- M:. - 1991. - P.544.

13. Kondratyeva T.S., Ivanova L.A., Zelikson Yu.I. and others // Technology of dosage forms. - M:. - “Medicine”, 1991.- vol. 1.- pp. 38-44.

14. Classification and organization of premises for the production of non-sterile medicines // Methodological instructions. MU 64-02-005-2002. - 2003. - N R-15.- P.2.

15. Krasnyuk I.I., Pharmaceutical technology // Technology of dosage forms Pod. Ed. Krasnyuk I.I., Mikhailova G.V. - M.: Academy. - 2004. - P. 464.

16. Milovanova L.N. Manufacturing technology of dosage forms. Rostov-on-Don: Medicine.- 2003.- P.448.

17. Muravyova D.A., Samylina I.A., Yakovlev G.P., Pharmacognosy. M.: Medicine. - 2003.- P. 656.

18. Sinev D.I. Reference manual on pharmacy technology of drugs. SPb.:

Nevsky Dialect, ed. - SPHFA St. Petersburg. - 2003- P.316.

19. STB 1433-2004. Production of medicines // Technological documentation. Minsk, Gosstandart. - 2004. - P. 323.

20. Chueshov V.I. Industrial technology of drugs: Textbook. In 2 volumes. Volume 1/V.I. Chueshov, O.I. Zatsev, S.T. Shebanova, M.Yu. Chernov. - Ed. NFAU.- 2002.- P.506.

21. Yarnykh T.G. Technology of drugs Tikhonov A.I., Yarnykh T.G., - M.: Mir. - 2003. - P.704.

Internet resources:

22. https://medi.ru/instrukciya/solodki-sirop_6532/

23. https://studfiles.net/preview/5874586/page:2/

24. https://studfiles.net/preview/5792348/page:3/

Posted on Allbest.ru

Similar documents

Feasibility study of production. Characteristics of finished products, raw materials and materials. Technological production process, material calculation. Recycling of industrial waste and environmental assessment of technological solutions.

training manual, added 05/03/2009

Chemical, technological and instrumental scheme for the production of 0.9% sodium chloride solution for injection. Characteristics of raw materials and description of the technological process, waste disposal. Production control and technological process management.

course work, added 11/18/2010

Consumption of soft non-alcoholic drinks in the Russian Federation. Characteristics of raw materials, intermediate products, auxiliary materials used in the production of soft drinks. Preparation of color and blended syrup. Storage and transportation of products.

course work, added 03/10/2014

Technological process of tile production at the Lipetsk Ceramic Plant. Laboratory structure and equipment, laboratory testing methods. Experimental control of the quality, properties and composition of raw materials for the production of ceramic tiles.

course work, added 02/25/2012

Organization of the technological process for the production of PF-115 enamel: choice of production method; characteristics of raw materials, materials and intermediate products. Equipment calculation, process automation. Labor protection and ecology. Feasibility study of the project.

thesis, added 12/06/2012

Characteristics of raw materials, semi-finished and auxiliary materials, finished products and production waste. Development of a production concept. Material calculation. Description of the hardware and technological scheme. Technological documentation.

thesis, added 01/10/2009

Methods for producing vinyl chloride. The choice of production method, its stages and description of the technological scheme. Characteristics of raw materials and finished product. Design and principle of operation of the main apparatus, auxiliary equipment. Environmental protection.

course work, added 01/08/2012

The technological process of manufacturing plates, its stages and requirements, nomenclature, process map. Material balance. Information about production waste, wastewater and atmospheric emissions, methods of their disposal, environmental protection.

course work, added 04/20/2014

The main stages of the technological scheme for the production of polyethylene pipes. Features of preparation and loading of raw materials, preparation of compositions. Extrusion of polyethylene with the formation of a pipe blank. Vacuum calibration, drawing, cooling and cutting.

abstract, added 10/07/2010

Description of the design, operating principle and drawing of the kinematic diagram of a continuous freezer. Machine and hardware diagram of the production line for ice cream in waffle cups. Freezing in boiling refrigerant. List of labor protection requirements.

Sugar-based syrup has gained high popularity in the culinary world. The composition is used for baking and preparing alcoholic beverages. It is also used as a base for fruit jams. It is not difficult to prepare sugar syrup if you have basic knowledge.

Methods for producing sugar syrup

First of all, decide what the sugar syrup is for. After this, start preparing the filling. Let's look at popular recipes.

Sugar syrup: a classic of the genre

- granulated sugar - 150 gr.

- clean water - 150 ml.

- Pour water into a small container and bring the mixture to a boil. Next, pour the sand into a heat-resistant container and fill it with hot liquid.

- Stir the ingredients until the sweet mass is smooth. After this, cool the syrup naturally and strain. Use the fill as intended.

Sticky sugar syrup

- purified water - 200 ml.

- sugar - 400 gr.

- Place the bowl of liquid in a water bath, add granulated sugar, stir the mixture until the crystals are completely dissolved.

- Cool the resulting mass at room temperature. This syrup is often used for confectionery purposes.

Caramel syrup

- granulated sugar - 950 gr.

- drinking water - 1.5 l.

- vanillin - 4 gr.

- Add 350 gr. sand in a separate enamel pan. Send the container over low heat, simmer the mixture until the granules are completely dissolved and a golden color appears.

- Then add the remaining ingredients to the total mass and mix thoroughly. Simmer the syrup at minimum power for 12-15 minutes. Next, the mass is filtered through gauze.

Inverted sugar syrup

- sugar - 2 kg.

- drinking water - 1.2 l.

- citric acid - 20 gr.

- Combine sand and water in an enamel pan. Bring the mixture to a boil over low heat. If a characteristic plaque appears, it should be removed.

- After this, add citric acid, mix thoroughly and simmer under the lid for about 25-30 minutes. Test the syrup for consistency with a wooden spatula. If a “thick thread” forms, the composition is ready.

- To achieve the desired consistency, you need to have an idea of what the pour will be used for. Most often, liquid, non-sticky syrup is used as an additive for soft drinks.

- Sugar syrup, which has a "thin thread", is determined by dipping two fingers into the cooled mixture. If the mixture flows in a thin stream and breaks off, be sure that the mixture is of high quality.

- More often, such syrup is used for alcoholic tinctures and liqueurs. A high-quality fill may not work the first time. Therefore, you will have to work hard to achieve the desired result.

- If the sugar syrup has a “middle thread”, it is often added to the base of fruit jams. The jet has a slightly larger size and some durability. A thicker and thicker thread of syrup tends to harden quickly.

9 stages of sugar syrup

Sugar-based liquid syrup

- The liquid composition is determined by the initial stage of the syrup; the preparation method implies that the temperature should not exceed 20 degrees.

- Sugar dissolves in warm water and has a liquid and non-sticky consistency. Such viscosity is achieved due to equal proportions of the constituent ingredients.

Thin thread of syrup

- To get the desired result in the form of a thin thread of sugar syrup, the mass must be brought to 100 degrees. In this case, the composition begins to boil, and the water begins to evaporate.

- The ratio of ingredients is 3 parts sugar to 1 part water. To determine consistency, drop a small amount of syrup onto a plate.

- After this, press the mixture with the convex part of a metal spoon. As a result, the mass should pull behind the household appliance like a thin thread. In this case, the syrup turns out thick and sticky.

Medium strand of sugar syrup

- To obtain a more viscous consistency, the syrup must be brought to a boil at a temperature of more than 102 degrees. The mass is mainly used as the main component for jam.

- Consider all possible factors when preparing such a sugar syrup. The thickness of the thread is checked in the same way as with a thin stream. The only difference is that the medium-sized thread has a more viscous and durable consistency.

Thick string of sugar syrup

- A thick mass is obtained if it is simmered at a temperature of about 110-112 degrees.

- Only 12-15% of liquid remains in the syrup. If you check the syrup with a spoon, then the mixture will stick out like a dense and thick thread.

Biscuit fondant

- To obtain impregnation for the biscuit, you need to place the syrup, which has reached 113 degrees, in cool water in time.

- As a result, you should get a loose, dense mixture. After preparation, use the fondant for its intended purpose.

Thick fondant

- To prepare a denser mass, the mixture should be brought to 115 degrees.

- Place the bowl of fudge in a bowl of cool water. At the end you will get a viscous thick mass.

Sugar syrup ball

- Sugar balls are mainly used to decorate confectionery products or for filling. The mass is boiled down to a state where 90% of sand remains in the composition.

- The mixture is cooked to a temperature of 118 degrees. If you cool it after cooking with cold water, you can end up rolling it into a ball. The composition remains soft even when completely cooled.

Hard ball of sugar-based syrup

- The preparation method is step-by-step, the mixture is heated over 119 degrees.

- After cooling, the ball becomes harder. If you try to bite through it, you may lose the filling on your teeth.

Sugar syrup caramel

- To prepare full-fledged caramel, the standard composition must be boiled until 2-3% of liquid remains in it.

- If you roll a ball from the resulting caramel, after cooling it can only be crumbled, like a candy. If you overdo it, you simply risk burning the sugar.

- As soon as you start cooking the syrup, do not forget to monitor its condition. Stir the mixture periodically until it is completely cooked.

- When the mixture reaches a homogeneous consistency and all the granules have dissolved, stop stirring frequently. Otherwise, air particles will get into the syrup and the sugar will crystallize.

- To prepare syrup, you need to choose thick-bottomed containers. This addition will help prevent the sugar from burning.

- You can also replace sand with powder. Keep in mind that you will need as much dust as sugar. Don't pay attention to the volume.

When the mixture reaches the first bubbles, it must be simmered over low, constant heat. Please take into account the fact that when the composition boils, it is prohibited to change the burner power until the syrup is completely cooked. It is also worth considering that after removing the container from the stove, the mass will continue to cook for some time. Cook the composition for the specified period, this way you will get the desired consistency.

Video: how to prepare invert syrup

Sugar plays an important role in shaping the taste of liqueurs. Sugar adds sweetness to the drink, softens the taste, and promotes the assimilation of aromatic substances. Sugar gives some drinks (creams, liqueurs) their characteristic thickness (viscosity).

Sugar is introduced into liquor products in the form of an aqueous solution; sugar syrup. To prevent the syrup from fermenting during storage, it is prepared very concentrated.

Sugar syrup is prepared with a concentration of 65.8% wt. (in 1 liter of syrup 869.3 g of sugar) and 73.2% wt. (1000.9 g of sugar in 1 liter of syrup) using hot and cold methods.

Preparing sugar syrup using the hot method. In the hot method, syrup is boiled in syrup boilers.

A typical syrup boiler is a closed cylindrical steel tank with a spherical bottom. The boiler is equipped with a steam jacket and a mechanical stirrer. The boiler lid has a hatch for loading sugar, a side pipe for filling water and an exhaust pipe for removing vapors. To drain the syrup there is a pipe in the bottom of the boiler. The drain hole of this pipe is closed by a valve moved with the help of the steering wheel. The boiler is heated by saturated steam supplied under a pressure of 0.3 MPa1

Softened water is supplied to the syrup boiler at the rate of 0.5 l per 1 kg of sugar (to obtain syrup with a concentration of 65.8% wt.) and 0.35 l per 1 kg of sugar (to obtain syrup with a concentration of 73.2% wt. ). The water is heated to 50--60 °C, after which, Stopping heating, add the calculated quantity of sugar with continuous stirring. After the sugar has completely dissolved, the solution is brought to a boil. Then, stopping the supply of steam from the surface, remove the foam from the syrup and heat it again to a boil. This operation is repeated twice.

The cooking time should not exceed 30 minutes, since prolonged heating of the syrup may cause caramelization of the sugar, resulting in yellowing or darkening of the syrup. The readiness of the syrup is determined by the concentration of sugar in it using a refractometer.

When preparing syrup with a concentration of 73.2%, before the end of cooking, citric acid is added to the boiler in the form of an aqueous solution in an amount of 0.08% relative to the mass of sugar.

After adding citric acid, the syrup should not be heated, since at high temperatures the inversion of sucrose is accompanied by the formation of furfural.

A mixture of glucose and fructose is called inverse sugar, which has a sweeter, milder and more pleasant taste and is much more difficult to crystallize than sucrose.

To separate mechanical impurities, the prepared hot syrup is filtered through a mesh filter (Fig. 37), which is a steel cylindrical body with a lid with hinged bolts and a flat bottom. In the upper part of the filter housing, on opposite sides there is one fitting for supplying syrup and another for its exit. The filter device (filter trap) consists of two mesh cups inserted one into the other. The inner glass has a hole with a diameter of 5 mm, the outer one with a diameter of 3 mm.